DJ FINCM Tsis Siv Neeg CNC Hlau Txiav Band Pom Tshuab

| TSIS MUAJ. | Khoom | Cov Qauv | ||||

| DJ500 | DJ700 | DJ1000 | DJ1250 | |||

| 1 | Qhov loj ntawm H-beam sawing (tsis muaj lub kaum sab xis tig) | 100 × 75~500 × 400 hli | 150 × 75~700 × 400 hli | 200 × 75~1000 × 500 hli | 200 × 75~1250 × 600 hli | |

| 2 | Qhov loj ntawm cov hniav txiav | T: 1.3 hli W: 41 hli | T: 1.6 hli W: 54 hli | T: 1.6 hli W: 67 hli | ||

| 3 | Lub zog tsav tsheb | Lub cev muaj zog loj | 5.5 kW | 11 kW | 15 kW | |

| Lub twj tso kua dej | 2.2kW | 5.5kW | 5.5kW | |||

| 4 | Kev ceev ntawm cov hniav pom | 20~80 m/feeb | 20~100 m/feeb | |||

| 5 | Txiav tus nqi pub | kev tswj hwm qhov kev pab cuam | ||||

| 6 | txiav lub kaum sab xis | 0°~45° | ||||

| 7 | Qhov siab ntawm lub rooj | Kwv yees li 800 hli | ||||

| 8 | Lub cev muaj zog hydraulic clamping tseem ceeb | 100ml/r | ||||

| 9 | Pem hauv ntej clamping hydraulic tsav | 100ml/r | ||||

| 10 | Qhov loj ntawm lub cav loj (L * w * h) | Txog li 2050x2300x2700mm | Txog li 3750x2300x2600mm | Txog li 4050x2300x2700mm | Txog li 2200x4400x2800 hli | |

| 11 | Qhov hnyav ntawm lub tshuab tseem ceeb | Kwv yees li 2500kg | Kwv yees li 6000kg | Kwv yees li 8800kg | Txog li 10t | |

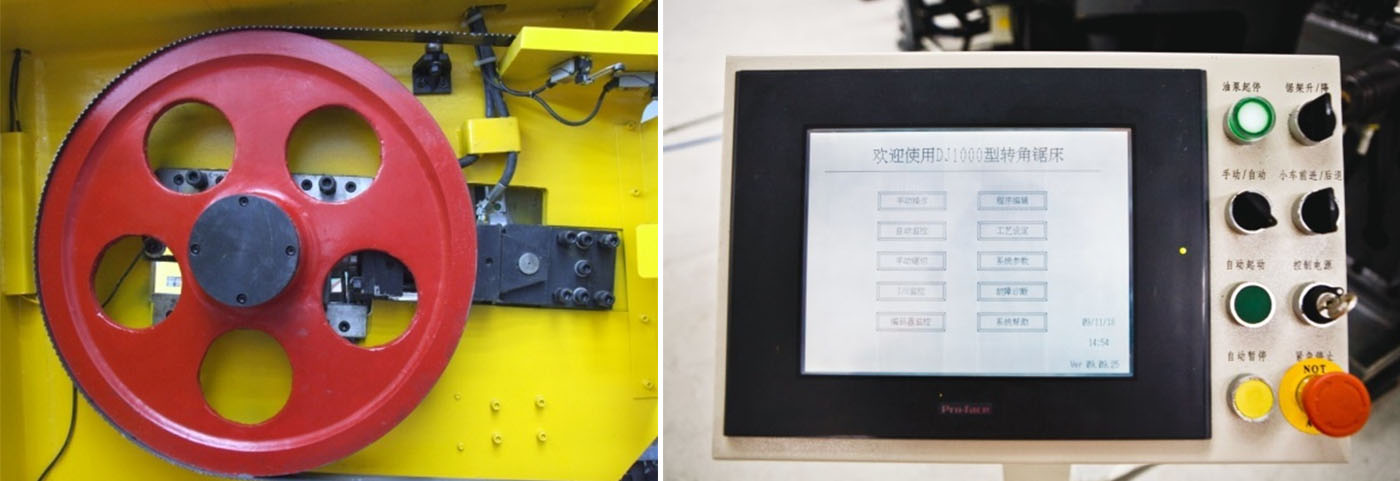

1. Lub tshuab no feem ntau yog tsim los ntawm CNC pub mis carriage, lub tshuab tseem ceeb, hydraulic system, hluav taws xob system thiab pneumatic system.

2. Lub thav duab sawing yog welded los ntawm cov yeeb nkab steel square thiab steel phaj, uas ua rau lub zog thiab qhov tseeb ntawm lub thav duab pom ruaj khov dua.

3. Lub thav duab pom tau txais hydraulic servo proportional valve thiab encoder, uas tuaj yeem paub txog kev pub zaub mov digital.

4. Lub tshuab muaj lub zog tseem ceeb nrhiav tam sim no, thaum lub cev muaj zog ua haujlwm ntau dhau, qhov ceev ntawm kev txiav yuav txo qis, uas txo qhov tshwm sim ntawm cov hniav pom raug "clamped"

5. Lub rooj sib hloov tau txais cov qauv thav duab, nrog kev ruaj khov zoo, kev ruaj khov muaj zog thiab seem sawing du.

6. Cov hniav saw hlau siv lub zog hydraulic, uas tuaj yeem tswj tau lub zog nruj zoo hauv kev txav mus los sai, txuas ntxiv lub neej ua haujlwm ntawm cov hniav sawing.

7. Lub tshuab ntxuav hmoov ntoo tsis siv neeg muaj lub txhuam fais fab tig rau ntawm lub thav duab hniav kom ntxuav cov hlau uas yuav lo rau ntawm hniav tom qab txiav.

8. Lub tshuab muaj lub luag haujlwm ntawm kev tig 0 ° ~ 45 ° Kev Ua Haujlwm: cov khoom siv beam tsis txav tab sis tag nrho lub tshuab tig, tom qab ntawd 0 ° ~ 45 ° txhua lub kaum sab xis ntawm lawv tuaj yeem txiav.

9. Lub tshuab CNC pub mis trolley yog tsav los ntawm lub iav khib tom qab lub cev muaj zog servo qeeb los ntawm lub reducer, yog li qhov chaw yog qhov tseeb.

| TSIS MUAJ. | Lub Npe | Hom | Lub teb chaws |

| 1 | Linear qhia kev tsheb ciav hlau | HIWIN/CSK | Taiwan, Suav teb |

| 2 | Lub cev muaj zog hydraulic | Justmark | Taiwan, Suav teb |

| 3 | Magnescale | SIKO | Lub teb chaws Yelemees |

| 4 | Lub twj tso kua dej | JUSTMARK | Taiwan, Suav teb |

| 5 | Lub tshuab hluav taws xob hydraulic | ATOS/YUKEN | Ltalis / Nyiv |

| 6 | Lub valve sib piv | ATOS | Ltalis |

| 7 | Cov hniav txiav | LENOX / WIKUS | Tebchaws Meskas / Lub Tebchaws Yelemees |

| 8 | Lub tshuab hloov zaus | KEV TXHIM KHO/KEV TXHIM KHO TSHIAB | Tuam Tshoj |

| 9 | PLC | Mitsubishi | Nyiv |

| 10 | Tlub vijtsam kov | Vaj Huam Sib Luag | Taiwan, Suav teb |

| 11 | Lub cev muaj zog servo | PANASONIC | Nyiv |

| 12 | Tus tsav tsheb servo | PANASONIC | Nyiv |

Cov Ntaub Ntawv Qhia Txog Lub Tuam Txhab  Cov Ntaub Ntawv Hoobkas

Cov Ntaub Ntawv Hoobkas  Muaj Peev Xwm Tsim Khoom Txhua Xyoo

Muaj Peev Xwm Tsim Khoom Txhua Xyoo  Kev Muaj Peev Xwm Ua Lag Luam

Kev Muaj Peev Xwm Ua Lag Luam