PD30B CNC Drilling Tshuab rau Phaj

| Khoom | Lub Npe | Tus nqi |

| Qhov Loj ntawm Phaj | Qhov tuab | Qhov siab tshaj plaws 80 hli |

| Dav x Ntev | 1600mm × 3000mm (Rau ib daim phaj) | |

| 1500 hli × 1600 hli (rau ob daim phaj) | ||

| 800mm × 1500mm (rau Plaub daim phaj) | ||

| Qhov taub ntawm qhov drilling | φ12-φ50mm | |

| Hom kev hloov kho ceev | Zaus Inverter stepless ceev hloov pauv | |

| RPM | 120-560r/feeb | |

| Kev pub mis | Kev hloov kho ceev hydraulic stepless | |

| Kev Tuav Phaj | Clamping tuab | Yam tsawg kawg nkaus 15 ~ Siab tshaj plaws 80 hli |

| Clamping lub tog raj kheej Nos. | 12 daim | |

| Lub zog clamping | 7.5KN | |

| Txias | Txoj Kev | Yuav tsum tau rov ua dua tshiab |

| Lub cev muaj zog | Lub Cev Muaj Zog Ntxaiv | 5.5kW |

| Lub Cev Muaj Zog Hydraulic Twj Tso Kua Mis | 2.2kW | |

| Tsav Tsheb Tshem Tawm Khoom | 0.4kW | |

| Lub Cev Muaj Zog Twj Tso Kua Txias | 0.25kW | |

| X Axis Servo Tsav Tsheb | 1.5kW | |

| Y Axis Servo Tsav Tsheb | 1.0kW | |

| Loj ntawm Tshuab | Ntev × Dav × Siab | Txog li 5560 × 4272 × 2855mm |

| Qhov hnyav | Tshuab tseem ceeb | Txog li 8000 Kg |

| Kev Mus Ncig Tebchaws | X-axis | 3000 hli |

| Y-axis | 1600 hli | |

| Qhov ceev tshaj plaws ntawm qhov chaw | 8000mm/feeb | |

1. Tshuab Ncej, 1 teeb

2. Gantry, 1 teeb

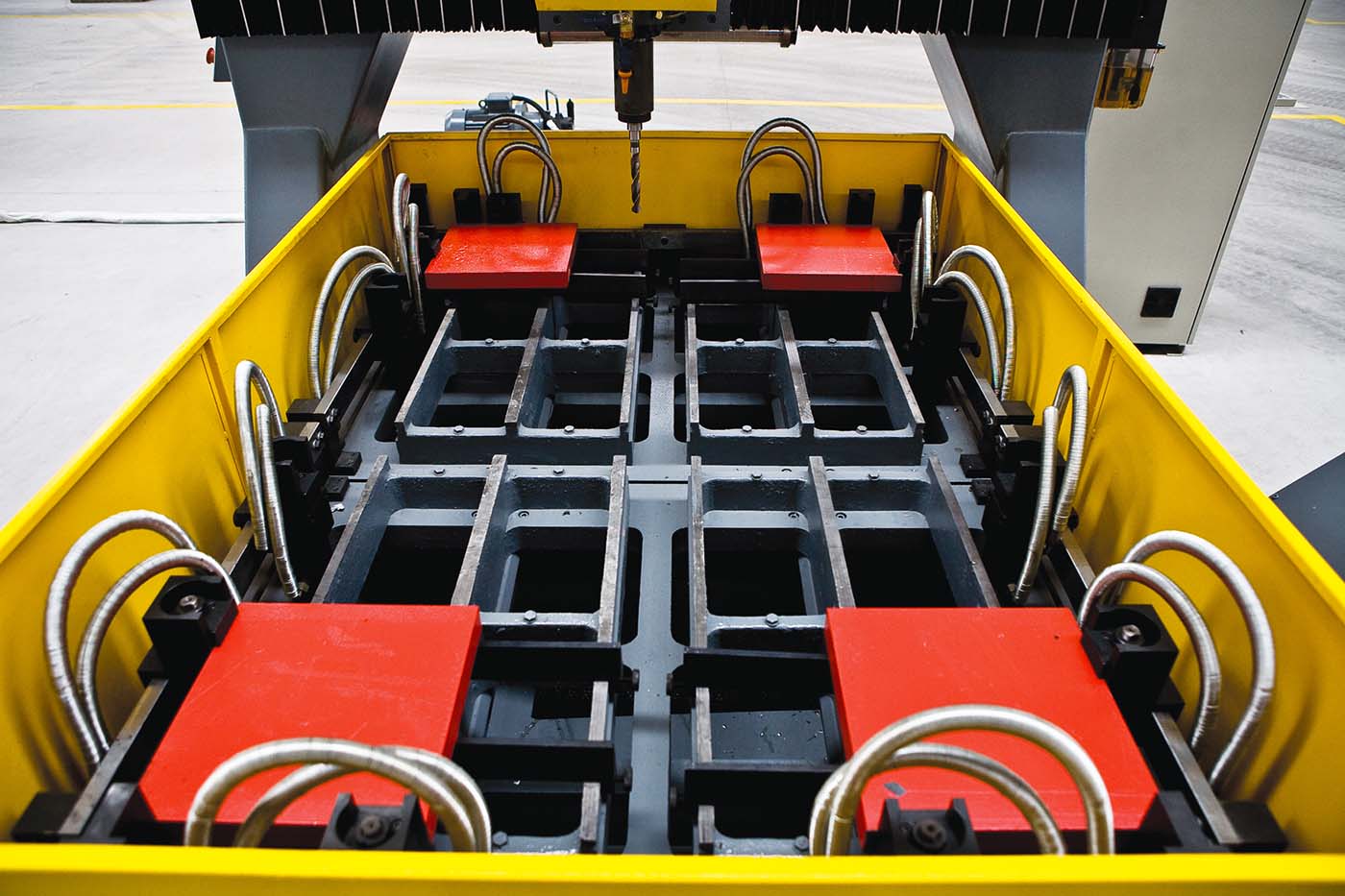

3. Txoj Haujlwm Sib Hloov Tau (Dual worktable), 1 teeb

4. Drilling Spindle, 1 teeb

5. Lub Tshuab Hydraulic, 1 teeb

6. Lub Tshuab Tswj Hluav Taws Xob, 1 teeb

7. Lub Tshuab Lubrication Hauv Nruab Nrab, 1 teeb

8. Cov Khoom Tshem Tawm, 1 teeb

9. Lub Tshuab Txias, 1 teeb

10. Hloov pauv sai ntawm lub cuab yeej drilling, 1 teeb

1. Lub tshuab Spindle Hydraulic tswj tsis siv neeg, uas yog peb lub tuam txhab patent technical know-how. Nws tuaj yeem ua tiav kev pub mov sai - ua haujlwm pub mov - rov qab sai, tsis tas yuav teeb tsa cov kev cai ua ntej ua haujlwm.

2. Txoj Haujlwm Sib Hloov Tau (Dual worktable) Ib lub rooj ua haujlwm tuaj yeem ua haujlwm tas li thaum lwm lub rooj ua haujlwm tseem tab tom upload / download cov khoom siv, uas tuaj yeem txuag lub sijhawm thiab txhim kho kev ua haujlwm ntau lawm.

3. Lub Tshuab Lubrication Centralized Cov khoom tseem ceeb tuaj yeem tau lubricated zoo, kom ruaj ntseg lub tshuab ua haujlwm zoo thiab lub neej ntev.

4. Lub tshuab cua txias Muaj lub cuab yeej siv rov ua dua tshiab rau cov lim dej txias.

5. PLC tswj system Cov software programming sab saud yog tsim los ntawm FIN CNC lub tuam txhab peb tus kheej, nws yooj yim heev thiab yooj yim rau kev khiav lag luam, nrog rau kev ceeb toom tsis siv neeg.

| Tsis yog. | Lub Npe | Hom | Lub teb chaws |

| 1 | Txoj kev qhia kab ncaj | CSK/HIWIN | Taiwan (Tuam Tshoj) |

| 2 | Lub twj tso kua dej | Tsuas yog Mark | Taiwan (Tuam Tshoj) |

| 3 | Lub qhov hluav taws xob electromagnetic | Atos/YUKEN | Ltalis/Nyiv Pooj |

| 4 | Lub cev muaj zog servo | Mitsubishi | Nyiv |

| 5 | Tus tsav tsheb servo | Mitsubishi | Nyiv |

| 6 | PLC | Mitsubishi | Nyiv |

| 7 | Khoos phis tawj | Lenovo | Tuam Tshoj |

Lus Cim: Cov saum toj no yog peb tus neeg muag khoom txheem. Nws yuav raug hloov los ntawm cov khoom zoo tib yam ntawm lwm hom yog tias tus neeg muag khoom saum toj no tsis tuaj yeem muab cov khoom yog tias muaj teeb meem tshwj xeeb.

Cov Ntaub Ntawv Qhia Txog Lub Tuam Txhab  Cov Ntaub Ntawv Hoobkas

Cov Ntaub Ntawv Hoobkas  Muaj Peev Xwm Tsim Khoom Txhua Xyoo

Muaj Peev Xwm Tsim Khoom Txhua Xyoo  Kev Muaj Peev Xwm Ua Lag Luam

Kev Muaj Peev Xwm Ua Lag Luam