PHD2016 CNC Tshuab Drilling Ceev Rau Cov Phaj Hlau

| Lub npe ntawm cov lus qhia | Cov khoom | Cov lus qhia txog lub valve |

| Phajqhov ntev | Cov khoom siv sib tshooj tuab | Siab tshaj plaws 100 hli |

| Dav × ntev | 2000mm × 1600mm | |

| Lub spindle | Kev tho qhov ntxaiv | BT50 |

| Dlub qhov dejqhovtxoj kab uas hla | Qhov siab tshaj plaws ntawm kev sib tw ntswj Φ50mm Qhov siab tshaj plaws ntawm kev siv hlau nplaum nyuaj Φ40mm | |

| Rqhov ceev ntawm lub cuab yeej(RPM) | 0-2000r/feeb | |

| Tqhov ntev ntawm txoj kab | 350 hli | |

| Lub zog hloov pauv zaus ntawm lub spindle | 15KW | |

| Phajclamp | Club teeb tuab | 15-100 hli |

| tus lej ntawm lub tog raj kheej clamp | 12 | |

| Lub zog clamp | 7.5kN | |

| Lub zog cua | Qhov xav tau roj av | 0.8MPa |

| Lub cev muaj zoglub hwj chim | Lub twj tso kua dej | 2.2kW |

| X-axis servo system | 2.0kW | |

| Y-axis servo system | 1.5kW | |

| Z-axis servo system | 2.0 KW | |

| Cov khoom siv thauj khoom chip | 0.75kW | |

| Kev mus ncig ntau yam | X qag | 2000 hli |

| Y qag | 1600 hli |

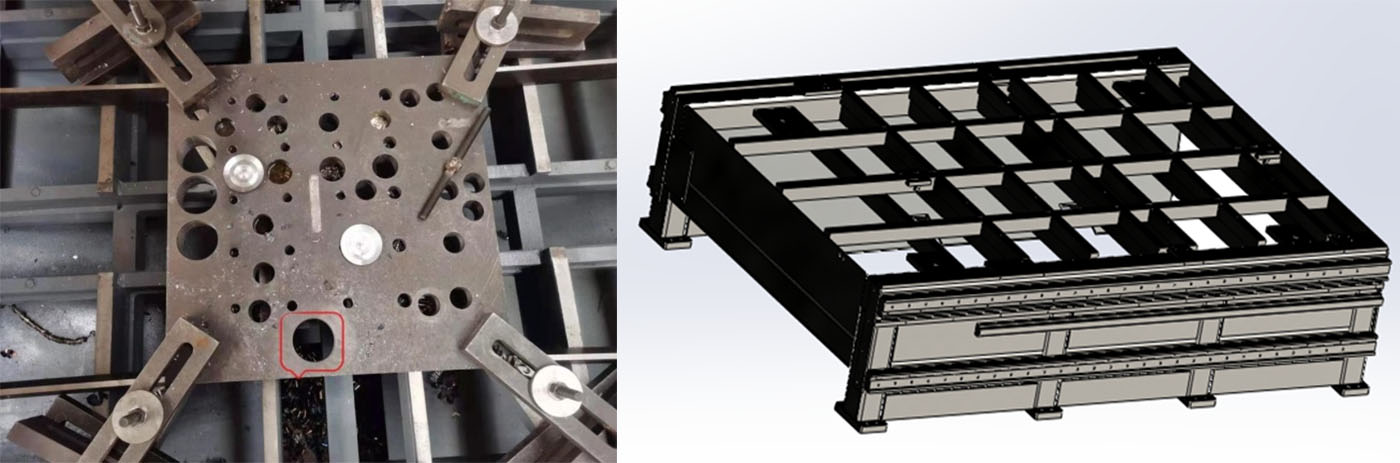

1. Lub tshuab no feem ntau yog tsim los ntawm txaj (worktable), gantry, drilling taub hau, hydraulic system, Electric control system, centralized lubrication system, txias chip tshem tawm system thiab lwm yam.

2. Nws txais yuav precision spindle nrog kev sib hloov siab thiab kev rigidity zoo.

3. Lub tshuab no ua tiav cov qhov pib thiab qhov kawg ntawm cov haujlwm nkag los ntawm software computer. Nws tsis tsuas yog tuaj yeem tho qhov hla cov qhov tab sis kuj tuaj yeem tho qhov dig muag, cov qhov stepped, thiab cov chamfers kawg ntawm lub qhov. Nws muaj kev ua haujlwm zoo, kev ntseeg siab rau kev ua haujlwm, kev teeb tsa yooj yim thiab kev saib xyuas.

4. Lub tshuab siv lub tshuab ua kom lubrication hauv nruab nrab es tsis txhob siv tes ua haujlwm kom ntseeg tau tias cov khoom ua haujlwm tau lubricated zoo, txhim kho kev ua haujlwm ntawm lub cuab yeej tshuab, thiab txuas ntxiv nws lub neej kev pabcuam.

5. Ob txoj kev txias sab hauv thiab sab nraud ua kom lub taub hau laum txias. Cov chips tuaj yeem pov rau hauv lub tsheb thauj khoom tau.

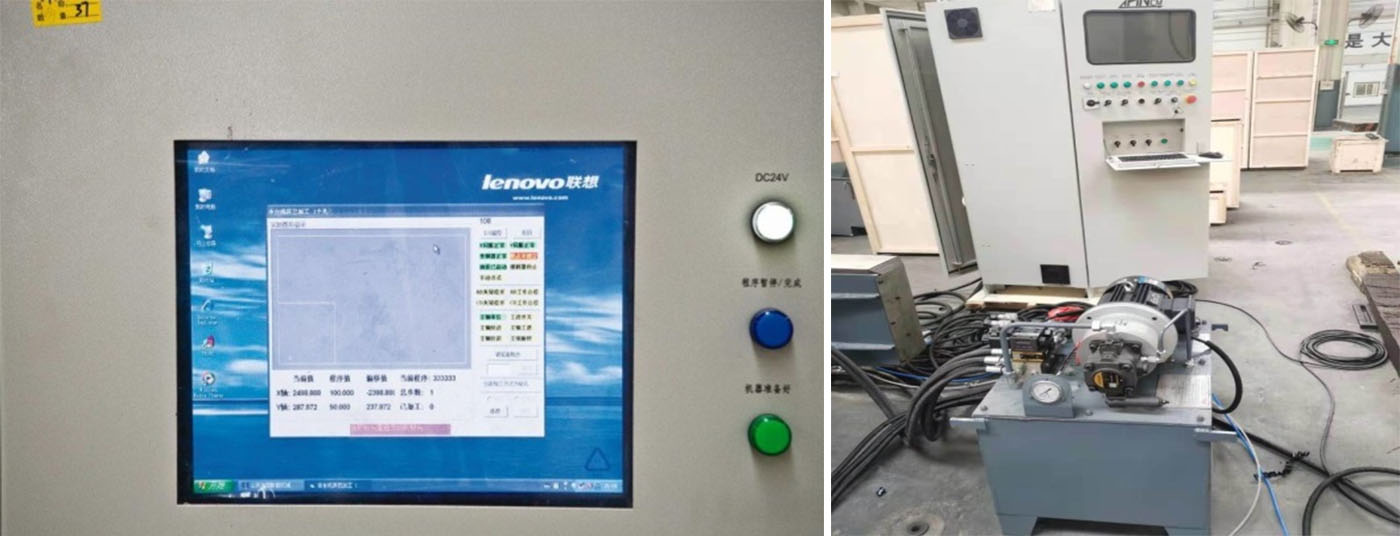

6. Lub kaw lus tswj hwm siv cov software programming computer sab saud uas yog tsim los ntawm peb lub tuam txhab thiab phim nrog cov programmable controller, uas muaj qib siab ntawm automation.

| TSIS MUAJ. | Lub Npe | Hom | Lub teb chaws |

| 1 | Txoj kev qhia kab ncaj | CSK/HIWIN | Taiwan (Tuam Tshoj) |

| 2 | Lub twj tso kua dej | Tsuas yog Mark | Taiwan (Tuam Tshoj) |

| 3 | Lub tshuab hluav taws xob hydraulic | Atos/YUKEN | Ltalis/Nyiv Pooj |

| 4 | Lub cev muaj zog servo | Mitsubishi | Nyiv |

| 5 | Tus tsav tsheb servo | Mitsubishi | Nyiv |

| 6 | PLC | Mitsubishi | Nyiv |

| 7 | Lub spindle | Kenturn | Taiwan, Suav teb |

| 8 | Khoos phis tawj | Lenovo | Tuam Tshoj |

Lus Cim: Cov saum toj no yog peb tus neeg muag khoom txheem. Nws yuav raug hloov los ntawm cov khoom zoo tib yam ntawm lwm hom yog tias tus neeg muag khoom saum toj no tsis tuaj yeem muab cov khoom yog tias muaj teeb meem tshwj xeeb.

Cov Ntaub Ntawv Qhia Txog Lub Tuam Txhab  Cov Ntaub Ntawv Hoobkas

Cov Ntaub Ntawv Hoobkas  Muaj Peev Xwm Tsim Khoom Txhua Xyoo

Muaj Peev Xwm Tsim Khoom Txhua Xyoo  Kev Muaj Peev Xwm Ua Lag Luam

Kev Muaj Peev Xwm Ua Lag Luam