PLD3020N Gantry Mobile CNC Phaj Drilling Tshuab

| Phajqhov loj | Phaj sib tshooj tuab | Siab tshaj plaws 100 hli |

| Width × ntev | 3000 hli × 2000 hliIb daim | |

| 1500 hli × 2000 hliTwo daim | ||

| 1000 hli × 1500 hliPlaubDaim | ||

| Pqhov axis ntawm qhov kawg | Qhloov lub chuck sai sai | Morse 3 thiab 4 taper qhov |

| Tshuab laumqhovtxoj kab uas hla | Φ12-Φ50mm | |

| Hom kev hloov pauv ceev | Kev hloov pauv ceev ntawm lub converter zaus tas mus li | |

| RPM | 120-560r/feeb | |

| Qhov ntev ntawm txoj hlab ntsha | 180 hli | |

| Kev pub tshuab | Kev tswj hwm ceev hydraulic tsis muaj kauj ruam | |

| Phajkev clamping | Clamping tuab | 15-100 hli |

| Tus naj npawb ntawm cov thooj voos kheej kheej clamping | 12 | |

| Lub zog clamping | 7.5KN | |

| Cov dej txias | Mzaj nkauj qhuas Vajtswv | Kev yuam kom muaj kev ncig |

| Ecov tshuab hluav taws xob | Lub cev muaj zog ntxaiv | 5.5kW |

| Lub cev muaj zog twj tso kua mis hydraulic | 2.2kW | |

| Lub cev muaj zog conveyor | 0.4kW | |

| Lub cav twj tso kua txias | 0.25kW | |

| X-axis servo motor | 1.5kW × 2 | |

| Y-axis servo motor | 1.0kW | |

| Qhov ntev ntawm tshuab | ntev × dav × siab | Txog li 6183 × 3100 × 2850mm |

| qhov hnyav | Tshuab | Kwv yees li 5500kg |

| Kev tshem tawm cov chip | Kwv yees li 400kg | |

| Tus naj npawb ntawm cov axes tswj | X. Y (taw tes tswj) Z (ntxaiv, pub hydraulic) | |

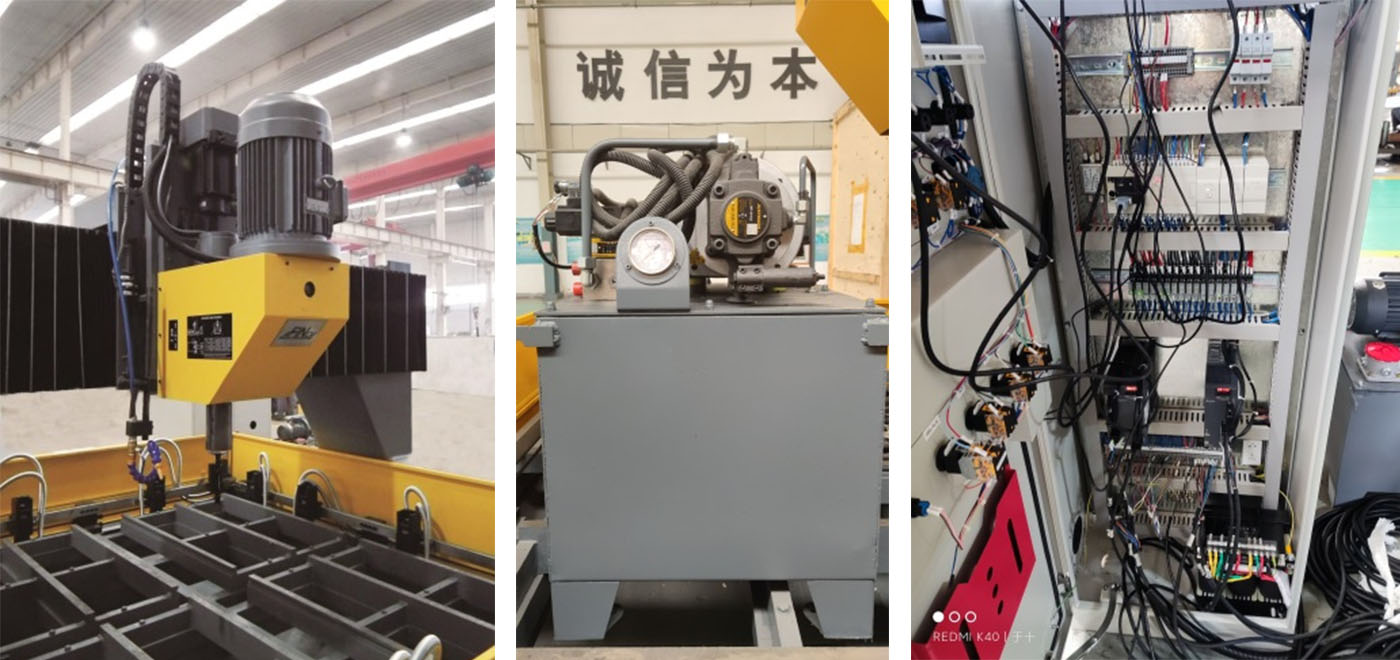

1. Lub cuab yeej tshuab feem ntau muaj txaj, gantry, lub taub hau fais fab drilling, hydraulic system, tswj system, centralized lubrication system, chip removal system, txias system, quick change chuck, thiab lwm yam.

2. Lub taub hau hydraulic tsis siv neeg stroke fais fab yog ib qho thev naus laus zis patented ntawm peb lub tuam txhab. Ua ntej siv, nws tsis tsim nyog los teeb tsa cov kev cai, thiab hloov pauv qhov ceev ceev mus tom ntej, ua haujlwm hauv thiab rov qab, thiab paub nws los ntawm kev sib xyaw ua ke ntawm cov khoom siv tshuab thiab hluav taws xob hydraulic.

3. Lub phaj raug clamped los ntawm hydraulic clamp, thiab tus neeg teb xov tooj raug tswj los ntawm ko taw hloov, uas yooj yim thiab txuag zog; Txog li 3000 ib daim × 2000mm, lub phaj me me tuaj yeem clamped rau hauv plaub lub ces kaum ntawm lub rooj ua haujlwm, uas ua rau lub sijhawm npaj ntau lawm luv dua thiab txhim kho kev ua haujlwm ntau lawm.

4. Muaj ob lub CNC axes hauv lub tshuab no: kev txav mus los ntawm gantry (x axis); Kev txav ntawm lub taub hau fais fab drilling ntawm lub gantry beam (Y-axis). Txhua lub CNC axis yog coj los ntawm cov lus qhia linear dov, tsav los ntawm AC servo motor thiab pob ntsia hlau. Kev txav mus los yooj ywm thiab qhov chaw raug.

5. Lub cuab yeej tshuab siv lub tshuab lubrication centralized es tsis txhob siv tes ua haujlwm, ua kom lubrication zoo ntawm cov khoom ua haujlwm, txhim kho kev ua haujlwm ntawm lub tshuab thiab ua kom lub neej ntawm lub tshuab ntev dua.

6. Lub tshuab cua txias siv dej txias ncig, thiab lub nozzle thoob ntiaj teb tau teeb tsa rau ntawm lub thawv drilling spindle, thiab cov dej txias ib txwm tsuag rau ntawm qhov chaw drilling ntawm lub phaj. Lub tshuab muaj lub cuab yeej lim dej txias ncig. Lub txaj muaj lub cuab yeej tshem cov chip, uas tuaj yeem tso cov chip tawm.

7. Qhov kev tswj hwm siv cov software programming computer sab saud uas peb lub tuam txhab tsim thiab phim nrog cov programmable controller.

| TSIS MUAJ. | Lub Npe | Hom | Lub teb chaws |

| 1 | Txoj kev qhia kab ncaj | CSK/HIWIN | Taiwan (Tuam Tshoj) |

| 2 | Lub twj tso kua dej | Tsuas yog Mark | Taiwan (Tuam Tshoj) |

| 3 | Lub qhov hluav taws xob electromagnetic | Atos/YUKEN | Ltalis/Nyiv Pooj |

| 4 | Lub cev muaj zog servo | Kev tsim kho tshiab | Tuam Tshoj |

| 5 | Tus tsav tsheb servo | Kev tsim kho tshiab | Tuam Tshoj |

| 6 | PLC | Kev tsim kho tshiab | Tuam Tshoj |

| 7 | Khoos phis tawj | Lenovo | Tuam Tshoj |

Lus Cim: Cov saum toj no yog peb tus neeg muag khoom txheem. Nws yuav raug hloov los ntawm cov khoom zoo tib yam ntawm lwm hom yog tias tus neeg muag khoom saum toj no tsis tuaj yeem muab cov khoom yog tias muaj teeb meem tshwj xeeb.

Cov Ntaub Ntawv Qhia Txog Lub Tuam Txhab  Cov Ntaub Ntawv Hoobkas

Cov Ntaub Ntawv Hoobkas  Muaj Peev Xwm Tsim Khoom Txhua Xyoo

Muaj Peev Xwm Tsim Khoom Txhua Xyoo  Kev Muaj Peev Xwm Ua Lag Luam

Kev Muaj Peev Xwm Ua Lag Luam