PLD3030A & PLD4030 Gantry Mobile CNC Drilling Tshuab

| Ilub npe ntawm lub npe | Cov Qauv | ||

| PLD3030A | PLD4030 | ||

| Kev ua haujlwm siab tshaj plawsphajqhov loj | Ntev x Dav | 3000x3000 hli | 4000 * 3000 hli |

| Qhov tuab | 200 hli | 100 hli | |

| Ua haujlwmrooj | Qhov dav ntawm T-groove | 22 hli | |

| Lub taub hau fais fab drilling | Qqhov ntau thiab tsawg | 2 | 1 |

| Qhov siab tshaj plaws ntawm kev khawbqhovtxoj kab uas hla | Φ12mm-Φ50mm | ||

| RPM(kev hloov pauv zaus) | 120-450r/feeb | ||

| Morse taper ntawm lub spindle | TSIS MUAJ. 4 | ||

| Lub zog ntawm lub cev muaj zog | 2x7.5kW | 5.5KW | |

| Qhov deb ntawm qhov kawg ntawm lub ntsej muaglub spindlemus rau lub rooj ua haujlwm | 200-550 hli | ||

| Kev txav mus los ntev ntawm Gantry (X-axis) | Kev mus ncig ntawm X-axis | 3000 hli | |

| X-axis txav ceev | 0-8m/feeb | ||

| Lub zog ntawm lub cev muaj zog servo ntawm X-axis | 2x2.0kW | ||

| X-axis qhov tseeb qhov chaw | 0.1 hli / Tag Nrho | ||

| Kev txav mus los ntawm sab nraud ntawm lub taub hau fais fab (Y-axis) | Qhov deb tshaj plaws ntawm ob lub taub hau fais fab ntawm Y axis | 3000 hli | |

| Qhov tsawg kawg nkaus ntawm ob lub taub hau fais fab ntawm Y axis | 470 hli | ||

| Y-axis servo lub cev muaj zog | 1.5KW | ||

| Kev txav ntawm lub taub hau fais fab | Kev mus ncig ntawm Z-axis | 350 hli | |

| Z-axis servo lub cev muaj zog fais fab | 2 * 2KW | ||

| Chip conveyor thiab cua txias | Lub zog ntawm lub cev muaj zog ntawm cov khoom siv thauj khoom nti | 0.75KW | |

| Lub zog ntawm lub twj tso kua mis txias | 0.45KW | ||

| Elub tshuab hluav taws xob | Tag nrho lub zog tsav tsheb | Txog li 30kW | Txog20kW |

| Tag nrho cov qhov ntev ntawm cov cuab yeej siv tshuab | Kwv yees li 6970x6035x2990 hli | ||

1. Qhov siab tshaj plaws ntawm lub tshuab cuab yeej drilling yog 50 hli, qhov siab tshaj plaws ntawm lub phaj drilling yog 200 hli, thiab qhov siab tshaj plaws ntawm lub phaj loj yog 3000x3000mm.

2. Lub cuab yeej tshuab muaj ob lub taub hau fais fab servo pub ywj pheej.

3. Qhov chaw sib koom ua ke ntawm lub qhov tuaj yeem tso tau sai ntawm qhov ceev ntawm 8m / feeb, thiab lub sijhawm pabcuam luv luv.

4. Lub tshuab hluav taws xob spindle ntawm lub taub hau drilling txais yuav kev tswj ceev zaus hloov pauv tsis tu ncua, thiab qhov ceev pub noj txais yuav kev tswj ceev servo stepless, uas yooj yim rau kev khiav lag luam.

5. Tom qab teeb tsa qhov drilling feed stroke, nws muaj qhov kev tswj hwm tsis siv neeg.

6. Lub qhov taper ntawm lub spindle yog Morse No. 4, thiab nws muaj Morse No. 4/3 reducer sleeve, uas tuaj yeem ntsia cov laum me me nrog ntau txoj kab uas hla.

7. Lub qauv txawb gantry tau txais yuav, lub tshuab npog thaj chaw me me thiab qhov kev teeb tsa qauv yog qhov tsim nyog.

8. Lub zog X-axis ntawm gantry txais yuav cov kabmob siab muaj peev xwm linear dov qhia kev tsheb ciav hlau khub kev taw qhia, uas yog hloov pauv tau.

9. Lub tshuab muaj lub cuab yeej teeb tsa lub caij nplooj ntoos hlav, uas tuaj yeem txheeb xyuas qhov chaw ntawm lub phaj tau yooj yim.

10. Lub kaw lus tswj hwm siv cov software programming computer sab saud uas peb lub tuam txhab tsim tawm thiab sib phim nrog PLC programmable controller, nrog rau qib siab ntawm automation.

11. Lub tshuab qhia kev tsheb ciav hlau thiab cov ntsia hlau txhuas tau nruab nrog lub tshuab roj tsis siv neeg.

12. X-axis qhia kev tsheb ciav hlau siv stainless hlau telescopic tiv thaiv npog, ob sab ntawm y-axis qhia kev tsheb ciav hlau siv lub hau tiv thaiv yooj ywm, thiab lub baffle dej tsis nkag ntxiv nyob ib ncig ntawm lub rooj ua haujlwm.

| TSIS MUAJ. | Lub Npe | Hom | Lub teb chaws |

| 1 | Linear qhia kev tsheb ciav hlau | HIWIN/PMI | Taiwan, Suav teb |

| 2 | Tus tsav tsheb servo | Mitsubishi | Nyiv |

| 3 | Slub cev muaj zog ervo | Mitsubishi | Nyiv |

| 4 | Tus maub los tswj tau | Mitsubishi | Nyiv |

| 5 | Lub tshuab roj tsis siv neeg | BIJUR/HERG | Tebchaws Meskas / Nyiv Pooj |

| 6 | Club computer | Lenovo | Tuam Tshoj |

Lus Cim: Cov saum toj no yog peb tus neeg muag khoom txheem. Nws yuav raug hloov los ntawm cov khoom zoo tib yam ntawm lwm hom yog tias tus neeg muag khoom saum toj no tsis tuaj yeem muab cov khoom yog tias muaj teeb meem tshwj xeeb.

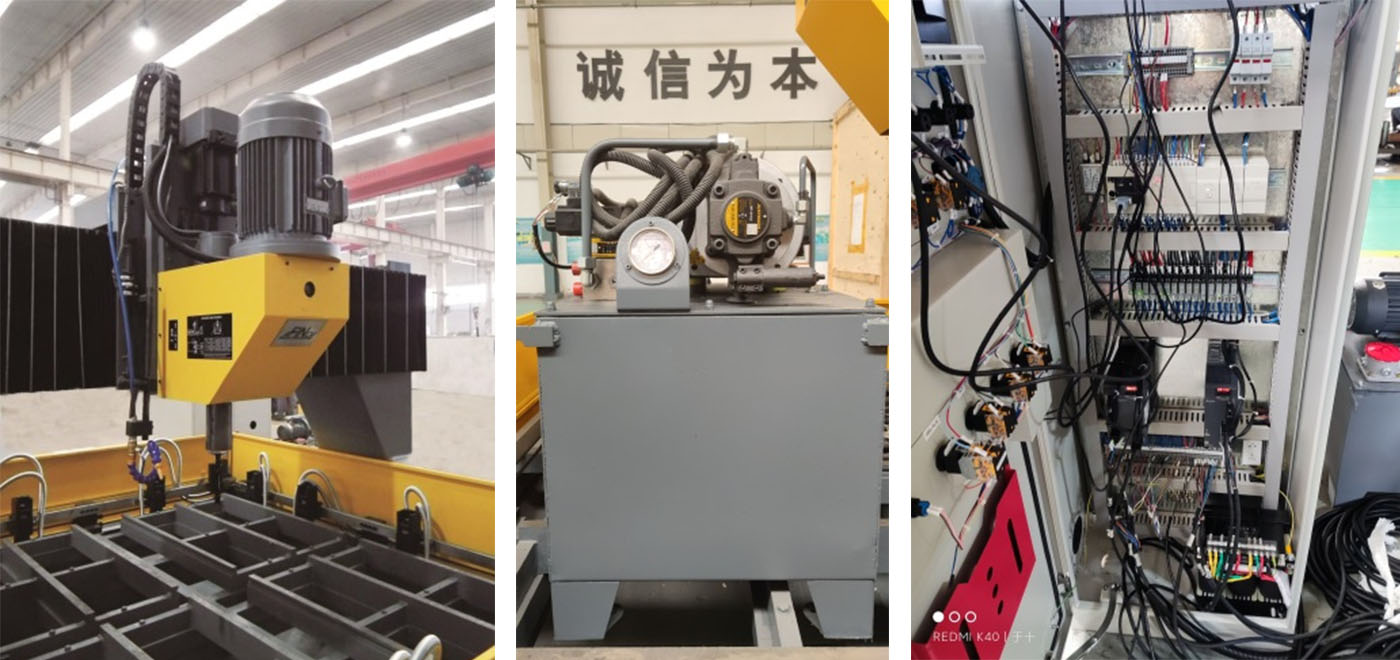

Cov Ntaub Ntawv Qhia Txog Lub Tuam Txhab  Cov Ntaub Ntawv Hoobkas

Cov Ntaub Ntawv Hoobkas  Muaj Peev Xwm Tsim Khoom Txhua Xyoo

Muaj Peev Xwm Tsim Khoom Txhua Xyoo  Kev Muaj Peev Xwm Ua Lag Luam

Kev Muaj Peev Xwm Ua Lag Luam