PLM4020 Gantry Movable CNC Phaj Drilling Tshuab Tshuab

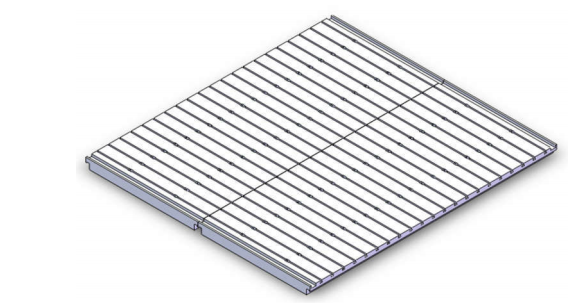

(1) Lub cev ntawm lub tshuab thiab lub nqaj hla yog ua los ntawm cov qauv welded, tom qab kev kho cua sov laus txaus, nrog qhov tseeb zoo heev. Lub rooj ua haujlwm, lub rooj txav mus los thiab lub ram tag nrho yog ua los ntawm hlau cam khwb cia.

(2) Ob sab 'ob lub servo tsav tsheb system ntawm X axis ua kom lub gantry txav mus los zoo, thiab qhov zoo ntawm Y axis thiab X axis.

(3) Lub rooj ua haujlwm siv cov qauv ruaj khov, cov hlau cam khwb zoo thiab cov txheej txheem casting siab heev, nrog rau lub peev xwm loj.

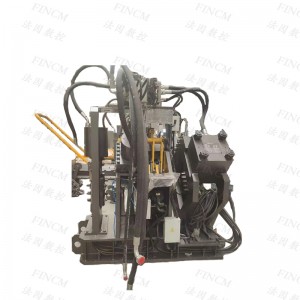

(4) Lub rooj zaum muaj zog heev, kev coj tus kheej siv txoj kev teeb tsa rov qab mus rau tom qab, kev coj tus kheej tshwj xeeb nrog cov ntsia hlau siab.

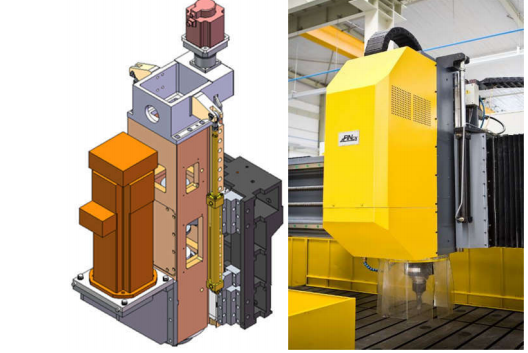

(5) Lub zog ntsug (Z-axis) txav ntawm lub taub hau fais fab yog coj los ntawm cov khub qhia kab sib dhos uas teeb tsa rau ob sab ntawm lub ram, uas muaj qhov tseeb zoo, tiv taus kev co siab thiab coefficient sib txhuam qis.

(6) Lub thawv fais fab drilling yog hom rigid precision spindle, uas siv Taiwan BT50 internal cooling spindle. Lub spindle cone qhov muaj lub cuab yeej purging, thiab siv tau cemented carbide internal cooling drill, nrog kev ua haujlwm siab. Lub spindle yog tsav los ntawm high-power spindle servo motor los ntawm synchronous siv, qhov piv txo qis yog 2.0, qhov ceev spindle yog 30 ~ 3000r / min, thiab qhov ceev ntau yog dav.

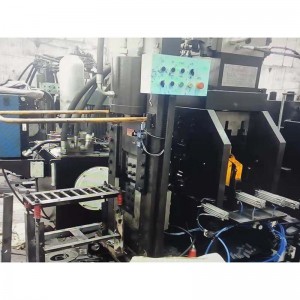

(7) Lub tshuab siv ob lub tshuab tshem cov hlau tawg tiaj tiaj rau ob sab ntawm lub rooj ua haujlwm. Cov hlau tawg thiab cov dej txias raug sau rau hauv lub tshuab tshem cov hlau tawg. Cov hlau tawg raug thauj mus rau lub thawv thauj cov hlau tawg, uas yooj yim heev rau kev tshem cov hlau tawg. Cov dej txias raug rov ua dua tshiab.

(8) Lub tshuab muab ob hom kev txias - txias sab hauv thiab txias sab nraud. Lub twj tso kua dej siab siab siv los muab cov dej txias uas xav tau rau kev txias sab hauv, nrog rau kev siab siab thiab ntws ntau.

(9) Lub tshuab muaj lub tshuab ua kom lubrication tsis siv neeg, uas twj cov roj lubricating rau hauv cov kab qhia kab sib txuas, pob ntsia hlau khub ntsia hlau txiv ntoo thiab dov cov kabmob ntawm txhua qhov tsis tu ncua kom ua tiav cov roj nplua nyeem txaus thiab txhim khu kev qha.

(10) Cov kev taw qhia X-axis ntawm ob sab ntawm lub tshuab tau nruab nrog cov hlau tsis xeb tiv thaiv, thiab cov kev taw qhia Y-axis tau teeb tsa nrog cov kev tiv thaiv hloov pauv tau.

(11) Lub cuab yeej tshuab kuj tseem muaj lub tshuab nrhiav ntug photoelectric los pab txhawb qhov chaw ntawm cov khoom ua haujlwm puag ncig.

(12) Lub cuab yeej tshuab tau tsim thiab teeb tsa nrog cov chaw muaj kev nyab xeeb tag nrho. Lub nqaj gantry tau nruab nrog lub platform taug kev, guardrail, thiab ntaiv nce toj ntawm sab ntawm kem kom ntseeg tau tias muaj kev nyab xeeb ntawm kev ua haujlwm thiab cov neeg ua haujlwm txij nkawm. Lub hau PVC mos mos tau teeb tsa nyob ib puag ncig lub ncej tseem ceeb.

(13) Lub tshuab CNC system muaj Siemens 808D lossis Fagor 8055, uas muaj cov haujlwm muaj zog. Lub interface ua haujlwm muaj cov haujlwm ntawm kev sib tham ntawm tib neeg thiab tshuab, kev them nyiaj yuam kev thiab lub tswb tsis siv neeg. Lub kaw lus muaj lub log tes hluav taws xob, uas yooj yim rau kev ua haujlwm. Nruab nrog lub khoos phis tawj nqa tau, CAD-CAM kev tswj hwm tsis siv neeg tuaj yeem ua tiav tom qab lub khoos phis tawj software sab saud tau teeb tsa.

| Khoom | Lub Npe | Tus nqi |

|---|---|---|

| Qhov Loj Tshaj Plaws ntawm Phaj | Ntev x Dav | 4000 × 2000 hli |

| Qhov Loj Tshaj Plaws ntawm Phaj | Txoj kab uas hla | Φ2000mm |

| Qhov Loj Tshaj Plaws ntawm Phaj | Qhov Siab Tshaj Plaws | 200 hli |

| Rooj Ua Haujlwm | Qhov Dav Dav ntawm T | 28 hli (tus qauv) |

| Rooj Ua Haujlwm | Qhov ntev ntawm lub rooj ua haujlwm | 4500x2000mm (LxW) |

| Rooj Ua Haujlwm | Qhov Hnyav Thauj Khoom | 3 tuj/㎡ |

| Drilling Spindle | Qhov Siab Tshaj Plaws ntawm Txoj Kab Uas Taub Hau | Φ60 hli |

| Drilling Spindle | Qhov siab tshaj plaws ntawm txoj kab uas hla | M30 |

| Drilling Spindle | Qhov ntev ntawm lub qhov drilling spindle vs. Qhov diameter ntawm lub qhov | ≤10 |

| Drilling Spindle | RPM | 30 ~ 3000 r / feeb |

| Drilling Spindle | Hom kab xev ntxaiv | BT50 |

| Drilling Spindle | Lub zog ntawm lub cev muaj zog | 22kW |

| Drilling Spindle | Qhov Siab Tshaj Plaws Torque (n≤750r/min) | 280Nm |

| Drilling Spindle | Qhov deb ntawm qhov chaw hauv qab ntawm Spindle mus rau lub rooj ua haujlwm | 280 ~ 780 hli (kho tau raws li cov khoom tuab) |

| Kev Tawm Tsam Ntev ntawm Gantry (X Axis) | Kev Mus Ncig Ua Si Ntau Tshaj Plaws | 4000 hli |

| Kev Tawm Tsam Ntev ntawm Gantry (X Axis) | Kev nrawm ntawm kev txav mus los ntawm X axis | 0 ~ 10m / feeb |

| Kev Tawm Tsam Ntev ntawm Gantry (X Axis) | Lub zog ntawm lub cev muaj zog ntawm X axis | 2 × 2.5kW |

| Kev Txav Mus Los Ntawm Spindle (Y Axis) | Kev Mus Ncig Ua Si Ntau Tshaj Plaws | 2000 hli |

| Kev Txav Mus Los Ntawm Spindle (Y Axis) | Kev nrawm ntawm kev txav mus los ntawm Y axis | 0 ~ 10m / feeb |

| Kev Txav Mus Los Ntawm Spindle (Y Axis) | Lub zog ntawm lub cev muaj zog ntawm Y axis | 1.5kW |

| Kev Tawm Tsam Pub Noj Ntxaib (Z Axis) | Kev Mus Ncig Ua Si Ntau Tshaj Plaws | 500 hli |

| Kev Tawm Tsam Pub Noj Ntxaib (Z Axis) | Kev pub ceev ntawm Z axis | 0 ~ 5m / feeb |

| Kev Tawm Tsam Pub Noj Ntxaib (Z Axis) | Lub zog ntawm lub cev muaj zog ntawm Z axis | 2kW |

| Qhov tseeb ntawm qhov chaw | X axis, Y axis | 0.08/0.05 hli/tag nrho kev mus ncig |

| Qhov tseeb ntawm qhov chaw rov ua dua | X axis, Y axis | 0.04/0.025mm/tag nrho kev mus ncig |

| Lub kaw lus hydraulic | Lub twj tso kua dej siab / Tus nqi ntws | 15MPa / 25L / feeb |

| Lub kaw lus hydraulic | Lub zog ntawm lub twj tso kua mis hydraulic | 3.0kW |

| Lub tshuab cua | Lub zog cua compressed | 0.5 MPa |

| Kev tshem tawm cov khib nyiab thiab lub tshuab cua txias | Hom kev tshem tawm cov khoom seem | Cov saw hlau phaj |

| Kev tshem tawm cov khib nyiab thiab lub tshuab cua txias | Kev tshem tawm cov khoom seem No. | 2 |

| Kev tshem tawm cov khib nyiab thiab lub tshuab cua txias | Kev ceev ntawm kev tshem tawm cov khoom seem | 1m/feeb |

| Kev tshem tawm cov khib nyiab thiab lub tshuab cua txias | Lub zog tsav tsheb | 2 × 0.75kW |

| Kev tshem tawm cov khib nyiab thiab lub tshuab cua txias | Txoj kev txias | Sab hauv txias + Sab nraud txias |

| Kev tshem tawm cov khib nyiab thiab lub tshuab cua txias | Siab Tshaj Plaws | 2MPa |

| Kev tshem tawm cov khib nyiab thiab lub tshuab cua txias | Qhov siab tshaj plaws ntawm kev ntws | 50L/feeb |

| Lub tshuab hluav taws xob | CNC tswj qhov system | Siemens 808D |

| Lub tshuab hluav taws xob | CNC axis naj npawb. | 4 |

| Lub tshuab hluav taws xob | Tag nrho lub zog | Txog li 35kW |

| Qhov Loj Tag Nrho | Ntev × Dav × Siab | Kwv yees li 10 × 7 × 3m |

| Tsis yog. | Lub Npe | Hom | Lub teb chaws |

|---|---|---|---|

| 1 | Cov menyuam linear qhia rail | Hiwin | Tuam Tshoj Taiwan |

| 2 | CNC tswj qhov system | Siemens / Fagor | Lub Tebchaws Yelemees/Spain |

| 3 | Kev pub mis ntawm servo lub cev muaj zog thiab servo tsav tsheb | Siemens/Panasonic | Lub teb chaws Yelemees/Nyiv Pooj |

| 4 | Lub spindle meej | Spintech/Kenturn | Tuam Tshoj Taiwan |

| 5 | Lub twj tso kua dej | Yuken/Justmark | Nyiv Pooj/Tuam Tshoj Taiwan |

| 6 | Twj tso roj | Justmark | Tuam Tshoj Taiwan |

| 7 | Lub tshuab roj tsis siv neeg | Herg/BIJUR | Nyiv Pooj/Asmeskas |

| 8 | Khawm, Qhov Qhia, cov khoom siv hluav taws xob qis | ABB/Schneider | Lub teb chaws Yelemees/Fabkis teb |

| Tsis yog. | Lub Npe | Loj | Ntau npaum li cas. |

|---|---|---|---|

| 1 | Optical ntug nrhiav | 1 daim | |

| 2 | Lub hau ntswj sab hauv hexagon | 1 teeb | |

| 3 | Tus tuav cuab yeej thiab rub lub pob tw | Φ40-BT50 | 1 daim |

| 4 | Tus tuav cuab yeej thiab rub lub pob tw | Φ20-BT50 | 1 daim |

| 5 | Cov xim seem | – | 2 lub thawv |

1. Lub zog muab hluav taws xob: 3 theem 5 kab 380 + 10% V 50 + 1HZ

2. Cua txias siab: 0.5MPa

3. Kub: 0-40 ℃

4. Av noo: ≤75%