RDS13 CNC Rail Saw thiab Drill Ua Ke Kab Ntau Lawm

| Khoom | tus qauv | Cov Lus Qhia Tshwj Xeeb |

| Qauv tsheb ciav hlau yooj yim | Hom khoom siv | 50Kg/m2,60 Kg/m2,75 Kg/m2 qhov nyuaj 340~400HB |

| Cov hlau alloy core rail, alloy steel ntxig, hardness 38 HRC~45 HRC | ||

| Qhov loj ntawm txoj kev tsheb ciav hlau | Qhov ntev ntawm cov khoom siv raw | 2000 xyoo~1250mm |

| Cov kev cai ua tiav | Khoom sivntev | 1300~800mm |

| Khoom sivqhov ntev kam rau siab | ±1 hli | |

| Qhov kawg ntawm lub ntsej muag perpendicularity | <0.5 hli | |

| Qhov taub ntawm qhov tho qhov | φ31~φ60 hli | |

| Qhov txoj kab uas hlakev kam rau siab | 0~0.5 hli | |

| Qhov siab ntawm qhov | 60~100 hli | |

| Cov txheej txheem tseem ceeb ntawm lub tshuab | Txoj kev txiav | Lub tshuab txiav voj voog (kev kub ceev) |

| Lub zog ntawm lub cev muaj zog | 37kW | |

| Lub taub hau hniav pom | Φ660mm | |

| Kev khiav ceev tshaj plaws ntawm X axis | 25m/feeb | |

| Qhov ceev tshaj plaws ntawm Z axis | 6m/feeb | |

| Drilling spindle hom | BT50 | |

| Kev khawb avQhov ceev ntawm lub ntxaiv | 3000r/feeb | |

| Kev khawb avLub zog ntawm lub cev muaj zog servo spindle | 37kW | |

| Qhov ceev tshaj plaws ntawm X, Y, Z axis | 12m/feeb | |

| Chamfering spindle hom | NT40 | |

| Chamfering spindle RPM Max. | 1000 | |

| Chamfering spindle lub cev muaj zog fais fab | 2.2 kW | |

| Kev txav ceev ntawm Y2 axis thiab Z2 axis | 10m/feeb | |

| Lub tshuab hluav taws xob tas mus li magnetic chuck | 250 × 200 × 140 hli (lwm tus200 × 200 × 140 hli) | |

| Kev nqus dej ua haujlwm | ≥250N/cm² | |

| Kev tshem tawm cov chip | 2teeb tsa | |

| Hom khoom siv thauj khoom nti | Cov saw hlau tiaj tiaj | |

| Kev tshem tawm cov chips sai | 2m/feeb | |

| Lub kaw lus CNC | Siemens828D | |

| Tus naj npawb ntawm cov tshuab CNC | 2 teeb | |

| Tus naj npawb ntawm CNC axes | 6 + 1 txoj kab,2 + 1axis | |

| Qhov siab ntawm lub rooj ua haujlwm | 700 hli | |

| Qhov siab ntawm lub rooj ua haujlwm | txog li 37.8m × 8m × 3.4m |

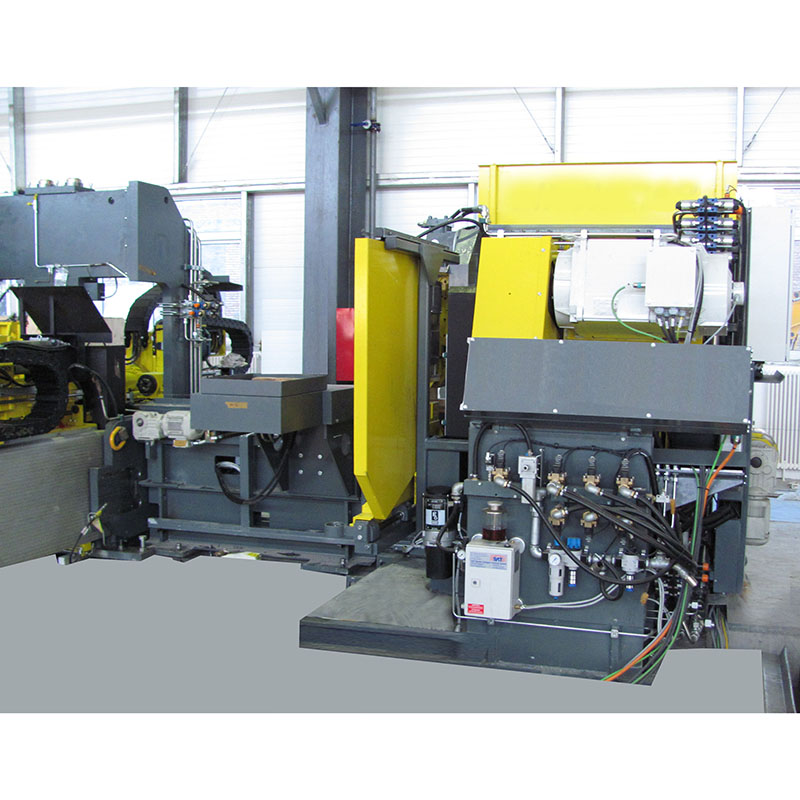

1. Muaj ib lub cuab yeej tshem tawm cov hniav txiav ntawm lub tshuab txiav, uas yog lub luag haujlwm tshem cov sawdust ntawm cov hniav txiav. Lub cuab yeej txias thiab lubricating ua rau lubricates thiab txias thaj chaw txiav, uas ua rau lub neej ntawm cov hniav txiav ntev dua. Cov kev taw qhia, thiab lub kem txawb tau teeb tsa rau ntawm lub txaj tshuab.

2. Lub kaw lus sau code

Lub tshuab coding tau teeb tsa rau sab nraud ntawm lub taub hau fais fab, thiab nws muaj lub khoos phis tawj tswj hwm los sau thiab tswj lub tshuab coding.

3. Chav tsev drilling

Cov qauv kem tau txais yuav, thiab kem tau txais cov qauv hlau welded. Tom qab annealing thiab kev kho kom zoo nkauj, qhov ruaj khov ntawm qhov tseeb ntawm kev ua tiav tau ua kom ntseeg tau.

4. Lub taub hau drilling

Lub taub hau drilling yog ib hom ram uas muaj zog rigidity. Lub siv sijhawm muaj lub zog tensile siab, lub neej ntev, suab qis thiab kev co qis thaum khiav ntawm qhov ceev ceev. Lub precision spindle yog txias sab hauv thiab hollow, thiab muaj 45 ° plaub-petal claw broach mechanism. Qhov kawg ntawm lub precision spindle yog nruab nrog lub hydraulic punching cylinder rau kev hloov cuab yeej yooj yim.

5. Rooj ua haujlwm

Lub rooj ua haujlwm siv cov qauv vuam hlau phaj, kev kho ua ntej yog ua ua ntej vuam, thiab tom qab vuam, kev txo kev ntxhov siab thiab kev kho cua sov laus yog ua kom ntseeg tau tias muaj tseeb thiab ruaj khov.

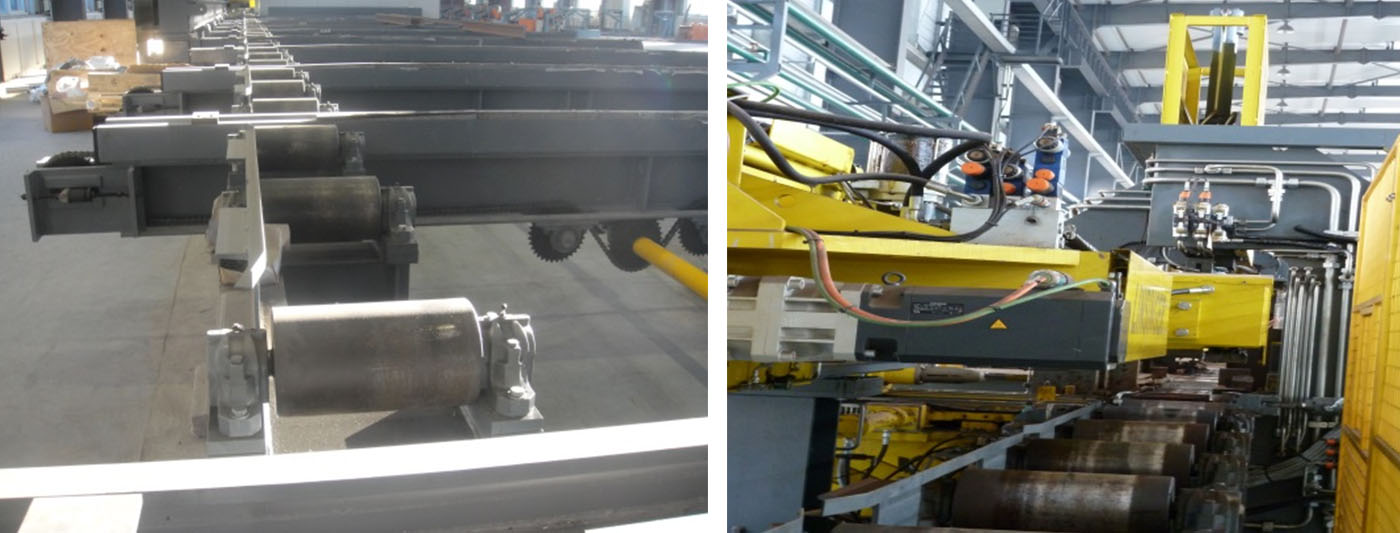

6. Lub kaw lus tshem tawm nti

Lub tshuab xa cov chips tsis siv neeg yog hom saw hlau tiaj tiaj, muaj tag nrho ob pawg. Ib pawg yog siv rau lub tshuab txiav thiab muab tso rau hauv qab ntawm sab ntawm lub hniav txiav. Lwm pawg yog siv rau lub tshuab drilling, uas muab tso rau ntawm lub txaj thiab lub rooj ua haujlwm. Cov ntaub ntawv hlau poob rau ntawm lub tshuab xa cov chips los ntawm cov lus qhia chip ntawm lub rooj ua haujlwm, thiab cov ntaub ntawv hlau raug thauj mus rau lub thawv ntaub ntawv hlau ntawm lub taub hau los ntawm lub tshuab xa cov chips.

7. Lub tshuab roj nplua nyeem

Muaj ob pawg ntawm cov tshuab ua kom lubrication tsis siv neeg, ib qho rau chav sawing thiab lwm qhov rau chav drilling. Lub tshuab ua kom lubrication tsis siv neeg ua lubrication tsis tu ncua ntawm cov kab linear rolling guide khub, pob ntsia hlau khub, thiab khib thiab pinion khub kom ntseeg tau tias lawv raug thiab lub neej ua haujlwm.

8. Lub tshuab hluav taws xob

Lub tshuab hluav taws xob siv Siemens 828D numerical control system, tag nrho ob pawg, ib pawg siv los tswj lub tshuab sawing, lub khib noj kab rov tav, lub rooj pub mov thiab lub rooj nruab nrab. Lwm pawg siv los tswj lub tshuab drilling, lub rooj ua haujlwm 1, lub khib tsis thauj khoom kab rov tav thiab lub rooj ua haujlwm.

| TSIS MUAJ. | Khoom | Hom | Keeb kwm |

| 1 | Kab qhia kev sib txuas | HIWIN | Taiwan, Suav teb |

| 2 | Lub kaw lus CNC 828D | Siemens | Lub teb chaws Yelemees |

| 3 | Slub cev muaj zog ervo | Siemens | Lub teb chaws Yelemees |

| 4 | Kev siv tshuab code | Lub tshuab luam ntawv LDMinkjet | Shanghai, Suav teb |

| 5 | Twj roj hydraulic | Justmark | Taiwan, Suav teb |

| 6 | Luag saw hlau | CPS | Kaus Lim Qab Teb |

| 7 | Cov iav, cov khib | APEX | Taiwan, Suav teb |

| 8 | Kev txo qis precision | APEX | Taiwan, Suav teb |

| 9 | Kev ntxaiv meej | KENTURN | Taiwan, Suav teb |

| 10 | Cov khoom siv hluav taws xob tseem ceeb | Schneider | Fabkis |

Lus Cim: Cov saum toj no yog peb tus neeg muag khoom txheem. Nws yuav raug hloov los ntawm cov khoom zoo tib yam ntawm lwm hom yog tias tus neeg muag khoom saum toj no tsis tuaj yeem muab cov khoom yog tias muaj teeb meem tshwj xeeb.

Cov Ntaub Ntawv Qhia Txog Lub Tuam Txhab  Cov Ntaub Ntawv Hoobkas

Cov Ntaub Ntawv Hoobkas  Muaj Peev Xwm Tsim Khoom Txhua Xyoo

Muaj Peev Xwm Tsim Khoom Txhua Xyoo  Kev Muaj Peev Xwm Ua Lag Luam

Kev Muaj Peev Xwm Ua Lag Luam