Tus nqi tsim nyog Tuam Tshoj OEM Kev Cai CNC Milling / Drilling / CNC Machining Kev Pabcuam rau Hlau Alloy Mechanical

Peb ua raws li txoj cai tswjfwm ntawm "Qhov zoo tshaj plaws yog qhov zoo tshaj plaws, Kev pabcuam yog qhov zoo tshaj plaws, Txoj Cai yog thawj zaug", thiab yuav ua siab dawb tsim thiab sib qhia kev vam meej nrog txhua tus neeg siv khoom rau tus nqi tsim nyog Tuam Tshoj OEM Kev Cai CNC Milling / Drilling / CNC Machining Service rau Hlau Alloy Mechanical, Peb yuav txhawb nqa tib neeg los ntawm kev sib txuas lus thiab mloog, Teeb tsa tus qauv rau lwm tus thiab kawm los ntawm kev paub dhau los.

Peb ua raws li txoj cai tswjfwm ntawm "Qhov zoo tshaj plaws yog qhov zoo tshaj plaws, Cov kev pabcuam yog qhov zoo tshaj plaws, Qhov xwm txheej yog thawj", thiab yuav ua siab dawb siab zoo tsim thiab sib qhia kev vam meej nrog txhua tus neeg siv khoom rauTuam Tshoj CNC Machining Service, Kev Pabcuam CNC Milling, Nrog rau cov khoom zoo tshaj plaws, kev pabcuam zoo heev, kev xa khoom sai thiab tus nqi zoo tshaj plaws, peb tau txais kev qhuas zoo los ntawm cov neeg siv khoom txawv teb chaws. Peb cov khoom lag luam tau raug xa tawm mus rau Africa, Middle East, Southeast Asia thiab lwm thaj chaw.

Cov Khoom Siv

| Khoom | Lub Npe | Tus nqi | |||||||

| PEM3030-2 | PEM4040-2 | PPEM5050-2 | PEM6060-2 | ||||||

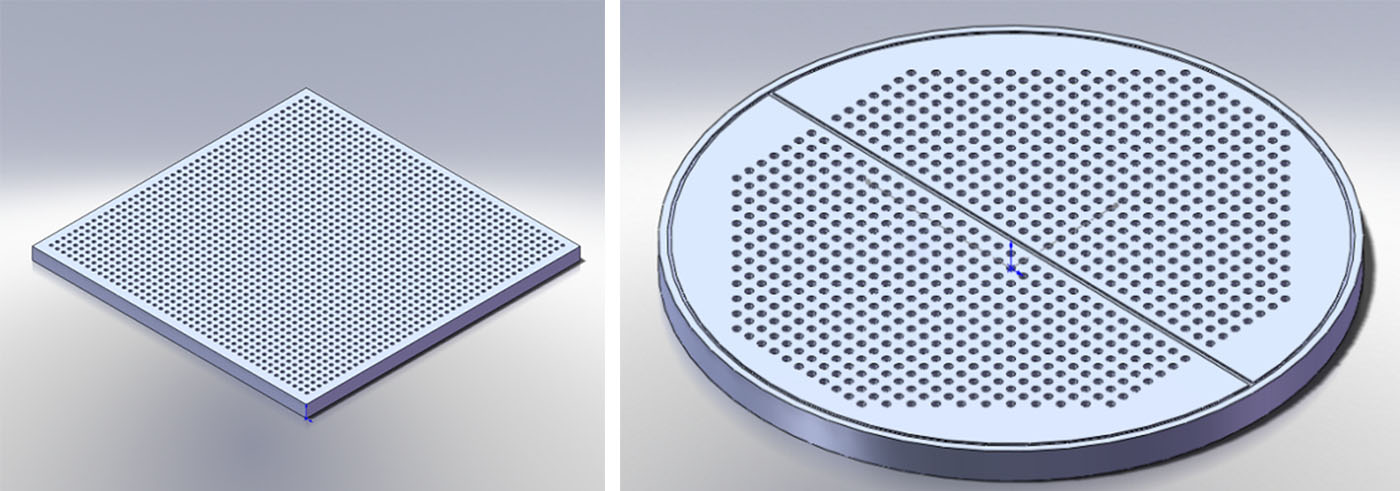

| Qhov Loj Tshaj Plaws ntawm Cov Khoom Siv Phaj | Ntev x Dav | 3000 * 3000 hli | 4000 * 4000 hli | 5000 × 5000 hli | 6000 × 6000 hli | ||||

| Qhov tuab ntawm cov khoom siv siab tshaj plaws | 250 hli (Tuaj yeem nthuav dav mus rau 380 hli) | ||||||||

| Rooj Ua Haujlwm | Qhov Dav Dav ntawm T | 28 hli (tus qauv) | |||||||

| Qhov Hnyav Thauj Khoom | 3ton/ | ||||||||

| Drilling Spindle | Qhov Siab Tshaj Plaws ntawm Txoj Kab Uas Taub Hau | Φ50 hli | |||||||

| Drilling spindle's Rod Length & Qhov diameter | ≤10 | ||||||||

| Daim kab xev ntxaiv | BT50 | ||||||||

| Lub zog ntawm lub cev muaj zog | 2 * 18.5kw / 22kw | ||||||||

| Qhov deb ntawm qhov chaw hauv qab ntawm Spindle mus rau lub rooj ua haujlwm | 280 ~ 780 hli (kho tau raws li cov khoom tuab) | ||||||||

| Qhov tseeb ntawm qhov chaw | X axis, Y axis | 0.06 hli/ tag nrho stroke | 0.10 hli/ tag nrho stroke | 0.12 hli/ tag nrho stroke | |||||

| Qhov tseeb ntawm qhov chaw rov ua dua | X axis, Y axis | 0.035mm / tag nrho stroke | 0.04 hli / tag nrho stroke | 0.05 hli / tag nrho kev mus ncig | 0.06 hli / tag nrho kev mus ncig | ||||

| Lub kaw lus hydraulic | Lub twj tso kua dej siab / Tus nqi ntws | 15MPa /22L/feeb | |||||||

| Lub zog ntawm lub twj tso kua mis hydraulic | 3 kW | ||||||||

| Lub tshuab cua | Lub zog cua compressed | 0.5 MPa | |||||||

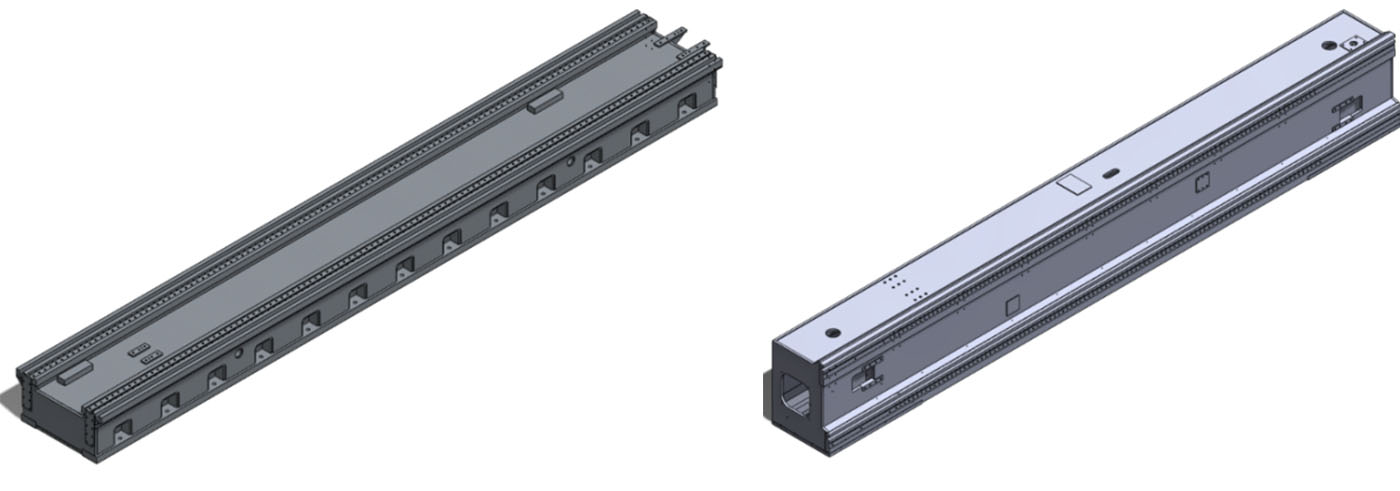

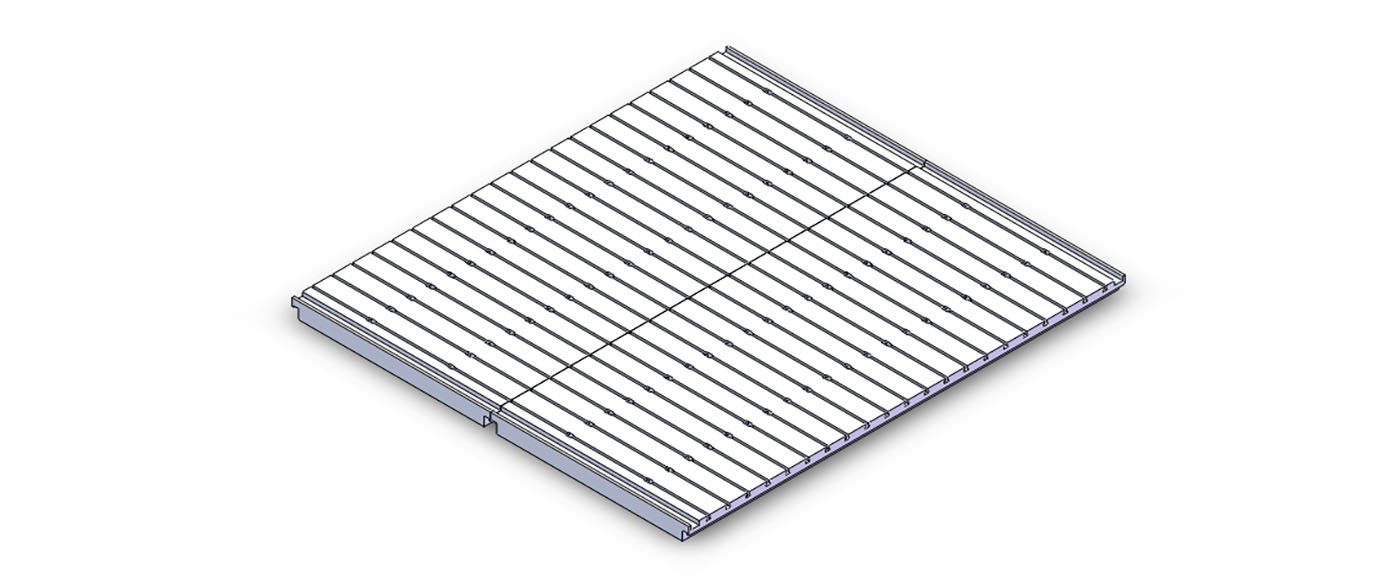

| Kev tshem tawm cov chip thiab lub kaw lus txias | Hom kev tshem tawm nti | Cov saw hlau phaj | |||||||

| Tus lej tshem tawm cov chip | 2 | ||||||||

| Kev tshem tawm cov chips sai | 1m/feeb | ||||||||

| Lub zog tsav tsheb | 2 × 0.75kW | ||||||||

| Txoj kev txias | Sab hauv txias + Sab nraud txias | ||||||||

| Siab Tshaj Plaws | 2MPa | ||||||||

| Qhov siab tshaj plaws ntawm kev ntws | 2 * 50L / feeb | ||||||||

| Lub tshuab hluav taws xob | Lub kaw lus CNC | KND2000 | |||||||

| Tus lej CNC Axis | 6 | ||||||||

| Tag nrho lub zog | Txog li 70kW | ||||||||

| Qhov Loj Tag Nrho | Ntev × Dav × Siab | Txog li 7.8 * 6.7 * 4.1m | Txog 8.8 * 7.7 * 1.1m | Kwv yees li 9.8 × 7.7 × 4.1m | Kwv yees li 10.8 × 9.7 × 4.1m | ||||

| Qhov hnyav ntawm lub tshuab | Txog 22Tons | Txog 30Tons | Txog li 35tons | Txog li 45tons | |||||

Cov ntsiab lus thiab qhov zoo

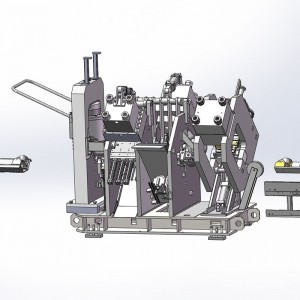

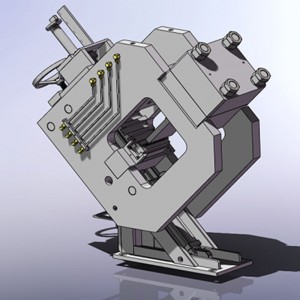

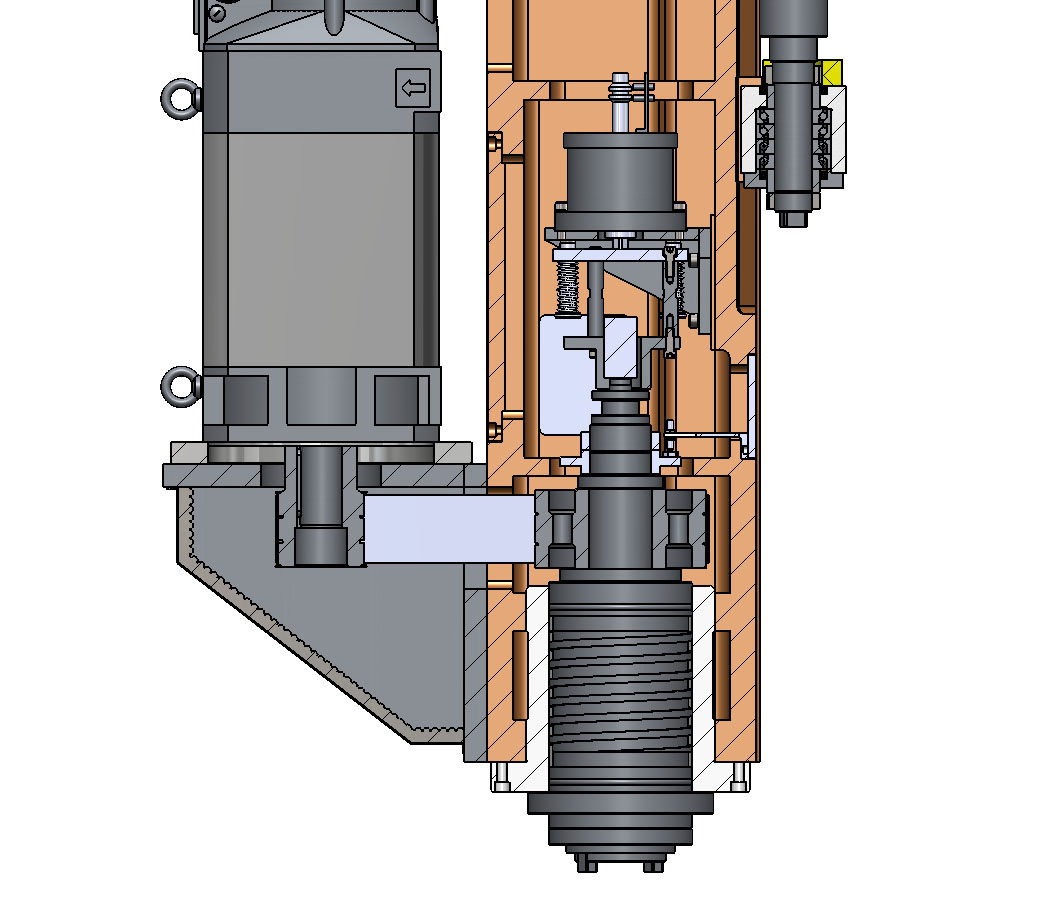

1. Lub tshuab no feem ntau yog tsim los ntawm lub txaj thiab kem, lub rooj tsavxwm thiab kab rov tav, lub thawv fais fab ntsug ram hom drilling, lub rooj ua haujlwm, lub tshuab xa khoom, lub kaw lus hydraulic, lub kaw lus pneumatic, lub kaw lus txias, lub kaw lus lubrication centralized, lub kaw lus hluav taws xob, thiab lwm yam.

2. Lub rooj zaum bearing muaj zog heev, cov bearing siv cov ntsia hlau siab. Lub hauv paus mounting ntev ntxiv ua kom muaj kev ruaj khov axial. Cov bearing raug ua ntej nruj los ntawm lub txiv ntseej xauv, thiab cov ntsia hlau lead raug ua ntej nruj. Qhov ncab yog txiav txim siab raws li qhov thermal deformation thiab elongation ntawm cov ntsia hlau lead kom ntseeg tau tias qhov tseeb ntawm cov ntsia hlau lead tsis hloov pauv tom qab kub nce.

3. Lub zog ntawm lub taub hau fais fab ntsug (Z-axis) yog coj los ntawm ob lub linear roller guides uas tau teeb tsa rau ntawm lub ram, nrog rau kev qhia zoo, kev co siab thiab kev sib txhuam qis. Lub pob ntsia hlau tsav los ntawm lub cev muaj zog servo los ntawm lub planetary reducer, uas muaj lub zog pub siab.

4. Lub tshuab no siv ob lub tshuab xa khoom tiaj tiaj rau ob sab ntawm lub rooj ua haujlwm. Cov hlau tawg thiab cov dej txias raug sau rau hauv lub tshuab xa khoom tawg, thiab cov hlau tawg raug thauj mus rau lub tshuab xa khoom tawg, uas yooj yim heev rau kev tshem tawm cov tawg; cov dej txias raug rov ua dua tshiab.

5. Lub tshuab no muaj ob txoj kev txias—txias sab hauv thiab txias sab nraud, uas muab cov roj nplua nyeem thiab txias txaus rau lub cuab yeej thiab cov khoom siv thaum txiav cov chip, uas lav qhov ua tiav zoo dua. Lub thawv txias muaj cov khoom siv kuaj xyuas qib kua thiab lub tswb ceeb toom, thiab lub siab txias txheem yog 2MPa.

6. Cov kev taw qhia X-axis ntawm ob sab ntawm lub tshuab tau nruab nrog cov hlau tsis xeb tiv thaiv, thiab cov kev taw qhia Y-axis tau nruab nrog cov kev tiv thaiv yooj ywm ntawm ob qho kawg.

7. Lub tshuab no kuj tseem muaj lub tshuab nrhiav ntug photoelectric los pab txhawb qhov chaw ntawm cov khoom siv voj voog.

Daim ntawv teev cov khoom tseem ceeb uas tau muab los ntawm lwm lub tuam txhab

| TSIS MUAJ. | YAM KHOOM | HOM | Keeb kwm |

| 1 | Cov menyuam linear qhia rail | HIWIN / CSK | Tuam Tshoj Taiwan |

| 2 | CNC tswj qhov system | SIEMENS | Lub teb chaws Yelemees |

| 3 | Kev pub mis ntawm servo lub cev muaj zog thiab servo tsav tsheb | SIEMENS | Lub teb chaws Yelemees |

| 4 | Lub spindle meej | SPINTECH/KENTURN | Tuam Tshoj Taiwan |

| 5 | Lub twj tso kua dej | YUKEN /JUSTMARK | Nyiv Pooj/ Suav Teb Taiwan |

| 6 | Twj tso roj | JUSTMARK | Tuam Tshoj Taiwan |

| 7 | Lub tshuab roj tsis siv neeg | HERG | Nyiv |

Lus Cim: Cov saum toj no yog peb tus neeg muag khoom txheem. Nws yuav raug hloov los ntawm cov khoom zoo tib yam ntawm lwm hom yog tias tus neeg muag khoom saum toj no tsis tuaj yeem muab cov khoom yog tias muaj teeb meem tshwj xeeb.

Peb ua raws li txoj cai tswjfwm ntawm "Qhov zoo tshaj plaws yog qhov zoo tshaj plaws, Kev pabcuam yog qhov zoo tshaj plaws, Txoj Cai yog thawj zaug", thiab yuav ua siab dawb tsim thiab sib qhia kev vam meej nrog txhua tus neeg siv khoom rau tus nqi tsim nyog Tuam Tshoj OEM Kev Cai CNC Milling / Drilling / CNC Machining Service rau Hlau Alloy Mechanical, Peb yuav txhawb nqa tib neeg los ntawm kev sib txuas lus thiab mloog, Teeb tsa tus qauv rau lwm tus thiab kawm los ntawm kev paub dhau los.

Tus nqi tsim nyogTuam Tshoj CNC Machining Service, Kev Pabcuam CNC Milling, Nrog rau cov khoom zoo tshaj plaws, kev pabcuam zoo heev, kev xa khoom sai thiab tus nqi zoo tshaj plaws, peb tau txais kev qhuas zoo los ntawm cov neeg siv khoom txawv teb chaws. Peb cov khoom lag luam tau raug xa tawm mus rau Africa, Middle East, Southeast Asia thiab lwm thaj chaw.

Cov Ntaub Ntawv Qhia Txog Lub Tuam Txhab  Cov Ntaub Ntawv Hoobkas

Cov Ntaub Ntawv Hoobkas  Muaj Peev Xwm Tsim Khoom Txhua Xyoo

Muaj Peev Xwm Tsim Khoom Txhua Xyoo  Kev Muaj Peev Xwm Ua Lag Luam

Kev Muaj Peev Xwm Ua Lag Luam