CNC Beam Peb-dimentional Drilling Tshuab

| Parameter tus nqi | ||||||||

| Parameter npe | Chav tsev | SWZ400-9 | SWZ1000C | SWZ1250C | ||||

| Scope ntawmBeam Dimension | Tshooj hlau | mm | 150 * 75-400 * 300 | 150 * 75-1000 * 50 | 150 * 751250 * 600 | |||

| Thickness | mm | ≤80 | ||||||

| Ntev | m | 12m (Configure raws li tus neeg thov) | 15m (Configure raws li tus neeg thov) | |||||

| Cov khoom siv luv luv | mm | Tsis siv neeg ua haujlwm ≥1500 | Tsis siv neeg ua haujlwm ≥3000 | |||||

| Kev tuav tes ua: ≤500 | Kev tuav tes ua: 690-3000 Nws | |||||||

| Spindle | Ntau | 3 | ||||||

| Drill qhov Ntau yam | Tsau sab, sab mobile | mm | ∅ 12 ~ ∅30 | ∅ 12 ~ ∅26.5 ib | ||||

| Intermediate unit | mm | ∅12 ~ ∅40 | ∅12 ~ ∅33.5 ib | |||||

| SpindleRPM | r / min | 180-560 : kuv | 180-560 : kuv | |||||

| Hloov daim npav lub taub hau sai | / | Morse taper qhov 4#(Tau hloov) | Morse taper qhov 4#(Tau hloov) | |||||

| Axial stroke | Tsau sab, sab mobile | mm | 140 | |||||

| Intermediate unit | mm | 325 | 240 | |||||

| Axial pub tus nqi | mm/min | 20-300 Nws | ||||||

| Tsiv deb | Txhua spindle yog nyob rau hauv cov kev taw qhia ntawmnqajntev | mm | 520 | |||||

| Ob sab ntawm spindle nyob rau hauv lub nce thiab nqis | mm | 35-470 : kuv | 35-570 : kuv | |||||

| Lub tsev nruab nrab yog nyob rau hauv cov kev taw qhia ntawmnqajdav | mm | 45-910 : kuv | 45-1160 : kuv | |||||

| Machining raug | Kev ua yuam kev ntawm qhov sib nrug ntawm qhov sib nrug hauv pawg qhov | mm | ≤ ±0.5 | |||||

| Pub mis yuam kev hauv 10 m ntev | mm | ≤ ±1 | ||||||

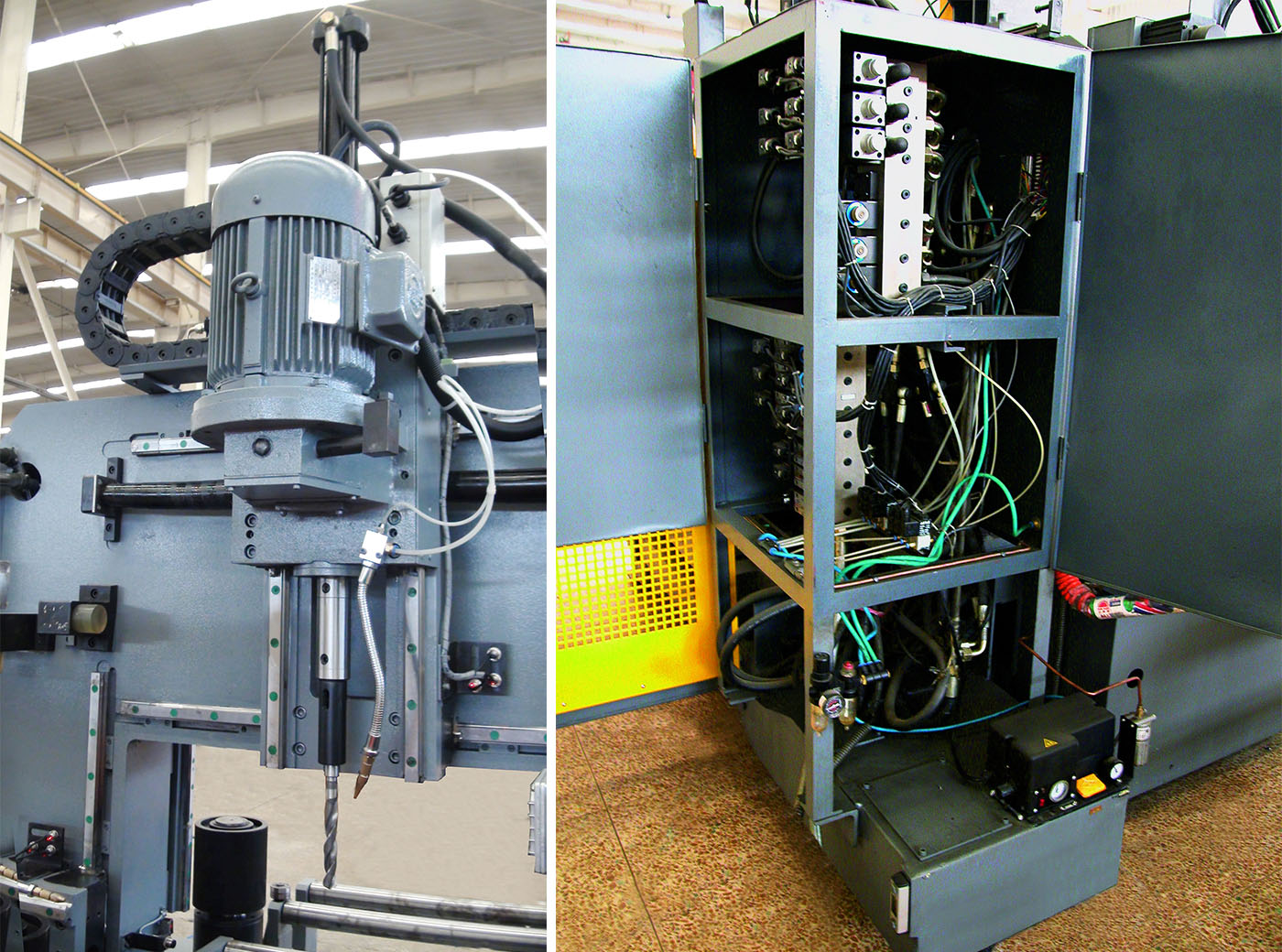

| Ehluav taws xoblub cev muaj zogzog | Peb theem asynchronous lub cev muaj zog rau spindle tig | kW | 4 * 3 | |||||

| Intermediate unit X-axis servo lub cev muaj zog | kW | 1.0 | 0.85 * 2 | |||||

| Z-axis servo lub cev muaj zog ntawm nruab nrab chav tsev | kW | 1.5 | 1.3 | |||||

| Tsau sab thiab txawb sab X-axis servo lub cev muaj zog | kW | 1.5 | 1.0 | 0.85 ib | ||||

| Tsau sab thiab txawb sab Y-axis servo lub cev muaj zog | kW | 1.5 | 1.5 | 1.3 | ||||

| Tsiv carriage peb theem asynchronous lub cev muaj zog | kW | 4 | 0.55 ib | 0.55 ib | ||||

| Tshaj qhov ntev | mm | 4.4 * 1.4 * 2.7 hli | 4.4 * 2.4 * 3.5 | 4.8 * 2.4 * 3.3 | ||||

| Lub tshuab lojQhov hnyav | kg | 4300 ib | 6000 | 7000 | ||||

1. Lub tshuab yog cov qauv thav duab welded los ntawm cov hlau zoo.Cov yeeb nkab steel yog muaj zog nyob rau hauv qhov chaw los ntawm kev ntxhov siab loj.Tom qab vuam, kev kho cua sov yog nqa tawm los txhim kho kev ruaj ntseg ntawm lub txaj.

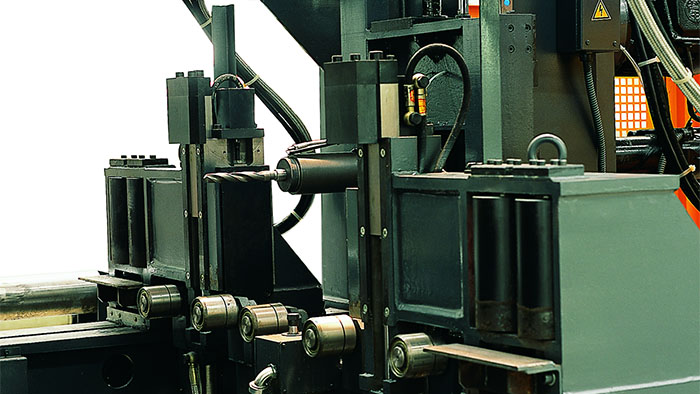

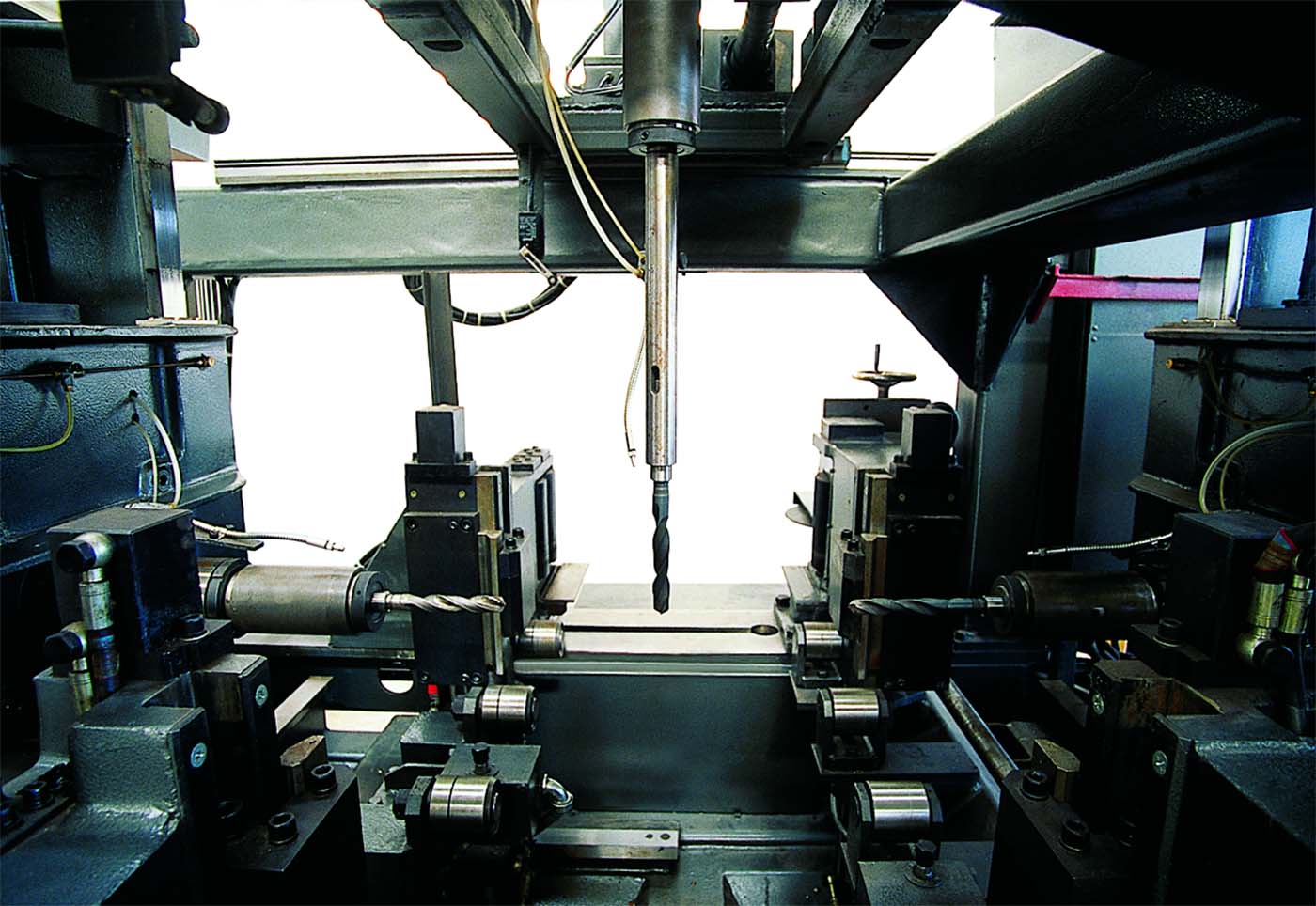

2. Muaj 3 CNC slides, 6 CNC axes ntawm txhua tus swb, thiab 2 CNC axes ntawm txhua tus swb.Txhua CNC axis yog coj los ntawm precision linear dov qhia thiab tsav los ntawm AC servo lub cev muaj zog thiab pob ntsia hlau.Lub qhov nyob rau tib seem ntawm cov nqaj tuaj yeem ua tiav tib lub sijhawm, uas ua rau muaj txiaj ntsig zoo ntawm qhov chaw thiab kev ua haujlwm ntawm lub qhov hauv pawg qhov.

3. Peb qhov kev tswj tsis siv neeg stroke drilling zog lub taub hau yog feem ntau ntsia ntawm peb CNC swb blocks rau kab rov tav thiab ntsug drilling.Peb lub taub hau drilling fais fab tuaj yeem ua haujlwm ntawm nws tus kheej lossis ib txhij.

4. Lub spindle ceev ntawm txhua lub taub hau drilling zog yog tswj los ntawm zaus converter thiab stepless hloov;kev pub ceev yog stepless hloov los ntawm kev ceev tswj valve, uas tuaj yeem hloov kho sai hauv ntau yam raws li cov khoom siv ntawm cov nqaj thiab txoj kab uas hla ntawm qhov drilling.

5. Lub nqaj yog tsau los ntawm hydraulic clamping mechanism.

6. Lub tshuab yog nruab nrog cov cuab yeej nrhiav kom pom ntawm qhov dav ntawm lub nqaj thiab qhov siab ntawm lub vev xaib, uas tuaj yeem hloov kho qhov yuam kev machining tshwm sim los ntawm qhov tsis sib xws ntawm cov khoom siv, thiab txhim kho qhov tseeb ntawm machining.

7. Cov cuab yeej siv lub tshuab yog nruab nrog lub tshuab ua kom txias txias, uas muaj qhov zoo ntawm cov khoom siv coolant tsawg, txuag nqi thiab hnav tsawg dua.

| TSIS MUAJ. | Lub npe | Hom | Lub teb chaws |

| 1 | Linear qhia rail | Hiav/CSK | Taiwan (Tuam Tshoj) |

| 2 | Electromagnetic hydraulic valve | Atos/Yua uken | Ltalis / Nyiv |

| 3 | Hydraulic twj tso kua mis | Justmark | Taiwan (Tuam Tshoj) |

| 4 | Servo lub cev muaj zog | Panasonics | Nyiv |

| 5 | Servo tsav tsheb | Panasonics | Nyiv |

| 6 | PLC | Mnws txoj kev | Nyiv |

| 7 | Txau lub twj tso kua mis txias | Bijur | Teb chaws USA |

| 8 | Flexible extension nozzle | Bijur | Teb chaws USA |

| 9 | Pneumatic solenoid valve | Airtac | Taiwan (Tuam Tshoj) |

| 10 | Centralized lubrication | Hua erg/Bijur | Nyiv/USA |

| 11 | Computer | Lenovo | Tuam Tshoj |

Lus Cim: Cov saum toj no yog peb tus qauv tsim khoom.Nws yuav raug hloov los ntawm cov khoom zoo tib yam ntawm lwm lub npe yog tias tus neeg muag khoom saum toj no tsis tuaj yeem muab cov khoom sib xws thaum muaj teeb meem tshwj xeeb.

Tuam txhab Profile  Cov ntaub ntawv Hoobkas

Cov ntaub ntawv Hoobkas  Kev Muaj Peev Xwm Txhua Xyoo

Kev Muaj Peev Xwm Txhua Xyoo  Muaj peev xwm ua lag luam

Muaj peev xwm ua lag luam